Magnetic Separators For Spices Industries – An Informative Guide

Most homes have a collection of spices in one of their kitchen cupboards. Adding spices to food when cooking is not only a common practice but essential for most culinary buffs. But how are the spices processed and prepared?

Spices are commonly grown in the equatorial regions of the world, with some thriving in the cool hazy highlands. Many of the seed spices come from more temperate areas, such as coriander seeds. The nature of the place, how the spices are collected, and the practice of processing and converting them into powders, mean that there is a high possibility of metal contamination. Most spice plants use a series of Magnetic Separators and Destoner and many other machines that help to remove and detect any problematic metal.

Different magnet materials have diverse properties, so the choice is very important.

Magnetic Destoner

Magnetic Destoners are majorly used to eliminate impurities from your product lines. Materials like stone, metallic, glass pieces, mud balls, black stones, rat feces, and other impurities that have natural magnetic properties are completely separated using the combination of magnetization and density separation (customizable option). These Magnetic Destoners are efficient, high-intensity, high-gradient, and durable machines used for a wide variety of separation applications including spices, coffee, beans, rice, and more.

The raw material or finished product is fed one or the other by gravity, air pumped, or a conveyor belt where it badges through or over a magnetic rod, grid, grate, or plate. The magnetic field captures the ferrous contamination by appealing it to the magnetic tube or plate. The non-magnetic clean product continues through the process. This process removes impurities from spices like red chilies, kebab masala, tikka masala, ginger, turmeric, garlic, coriander seasoning, black pepper, cumin, and many other spices that can be detached using our high-quality magnetic Destoner.

Hump Magnet

Magnetic humps are used where the flow of material is vertical. Hump magnets are mostly used to separate ferrous metals from Spices, granules, powder, food products, and others. Hump Magnets generally consist of two Plate Magnets attached to an offset housing and are installed in vertical columns. The spice material falling strikes directly on the first magnet changes direction and falls over the second magnet, ensuring clean outflow material.

This type of ferrous metal removal unit can be fitted simply in a remaining pipeline or outlet of various equipment like pulverizes, blenders, & classifiers or any other outlet location. In standard type, each unit comprises two permanent magnetic grids mounted one above the other. This works as the particles like magnet, mudballs and more are separated to make spices edible with no cause of harm.  Spout Magnet

Spout Magnet

The leading magnet is developed through the removal of ferrous metals from materials in granular spices and powder form during transport through pipeline systems. These magnet systems are built into a housing that is fitted with the flat projection that, after mounting, forms a single unit with the pipeline systems.

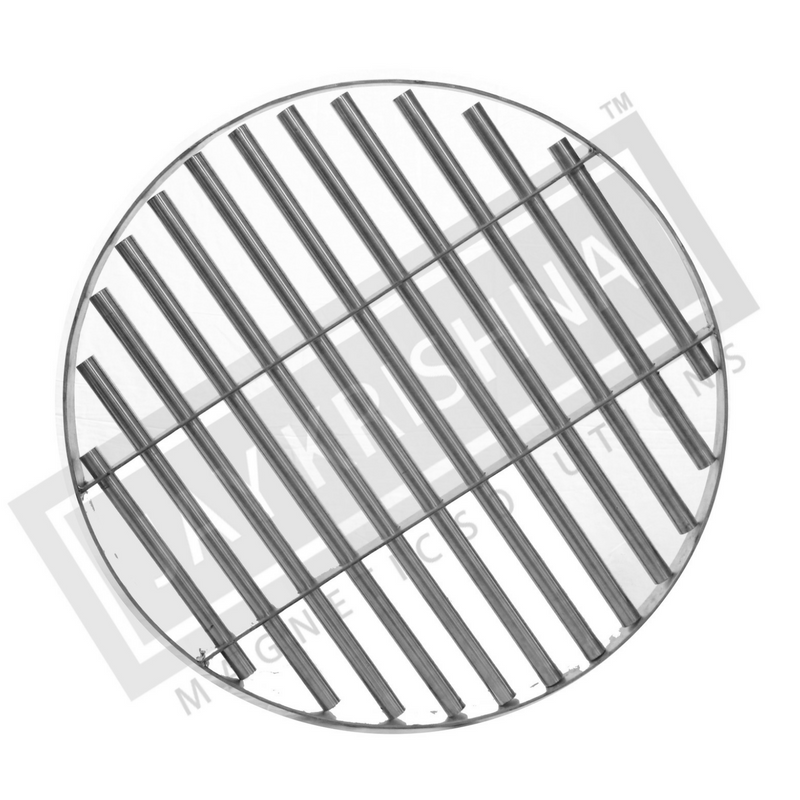

Magnetic Grill

The magnetic grill is made up of stainless steel high-intensity magnetic field to remove the magnetic particles from spices and powders. They are usually available in square, rectangle, and circle.

To Be Concluded

To Be Concluded

There are too many types of magnetic separators, but choosing and getting the wrong type results in too low separation efficiency. Considerations such as viscosity, type of metal pollution, density, moisture, pressure, and temperature are crucial for determining and getting the right magnetic separator for your specific process.

Jaykrishna Magnetics Pvt. Ltd. Guaranteeing consistent quality A production line with reliable quality and output. We are dedicated to making complex things much simpler and well-organized for our customers. For more information on this, contact us at info@jkmagnetic.com or contact us at +91 9825326078, +91 93274 46310

- Zorba Non-Ferrous Metal Separation Installed Line – A Detailed Guide

- The Difference Between Overband Magnetic Separator And Inline Magnetic Separator

- Everything You Should Know About Wet Drum Magnetic Separator

- Cost Effective Magnetic Separators For Pharmaceutical Powders

- Hygienic Magnetic Separators For Sensitive Dairy Powders