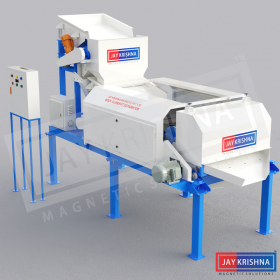

Jaykrishna Magnetics Pvt. Ltd. is the pioneer in magnetic separation technology worldwide & we’re India’s biggest manufacturers of Eddy Current Separators which are prominently used in industries as a separator of non-ferrous metals from mixed wastes and other main-stream materials. More specifically, It purely separates metals like aluminum, copper, brass and much more from your product stream, municipal solid waste recycling lines, scrap residues and other project lines.

We manufacture the eddy masterclass eccentric rotor design to ensure the full efficiency of eddy current effects on the rotor shell, that separates about 97% of your total non-ferrous impurities.

Our Product Video:

The principle of the eddy current separator is fairly straightforward. Basically, a rotor composed of magnet blocks in a parallel formation(either standard ferrite ceramic or NDFEB rare earth magnets) depending on the application; are spun at high-speed revolutions to produce an effect called “eddy currents”. These eddy currents react with different metals according to their mass and conductive resistivity, creating a repelling force on the charged particle. Now, If a metal is light yet conductive such as aluminum, it is easily levitated and ejected from the normal flow of the product stream (i.e main purpose of this separator). Separation of stainless steel is also possible depending on the grade of material.

Particles from material flows can be sorted down to a minimum size of 3/32″ (2mm) in diameter. There is no question that Eddy Current Separators have been a crucial development, not only for the recycling industry but many more manufacturing plants. In a world of depleting natural resources, the race is on to find faster, cheaper and more efficient ways of reclaiming and recovering raw materials, as well as improving the purity and reducing the risk of contamination during the processing.

Eddy current separators are the absolute holy grail in this fastest growing market of beverage can sorting, where they can provide an accurate separation of aluminum cans from waste streams.

Some of the most impactful and exciting innovations our machine des that we are proud of is helping to reduce environmental waste and damage to the environment by recovering valuable non-ferrous metals from municipal and industrial refuse.

Eddy Current Separator Manufacturing Unit For Large Orders:

Working Principle:

How Eddy Current Separator Work:

In an eddy current separator, there is a short belt of conveyors that has its drive located at the return end and a high-speed magnetic rotor system installed at the discharge end. This rotor, which is positioned within a separately rotating non-metallic drum, revolves at high-speeds during working, whilst the outer drum cover rotates at the speed of the eddy currents belt conveyor.

While the rotor spins, electric current is induced into the conducting metals of the flow. This current creates a magnetic field, which opposes the field created by the rotor, repelling the conducting metals over a pre-positioned splitter plate, completing the separation process. The remaining materials such as plastics, glass, and other dry recyclables will simply free-fall over the rotor, separating them from the repelled metals.

Functions:

The eddy current effect appears if non-ferrous conductors of electricity are exposed to an alternating magnetic field. The eddy currents in turn, generate fluxes which are opposed to the fields generating them, thus causing repulsive forces which discharge nonferrous metals out of the flow line.

Eddy Current Separator Specifications:

|

Model

|

Belt Width

|

Drum Size

(mm)

|

Drum

Separator Drive

|

1st Vibratory Motor

|

2nd Vibratory Motor

|

Belt

Drive

|

Rotor

Drive

|

|---|---|---|---|---|---|---|---|

| JECS-20 | 650mm | 300×500 | 0.5hp | 0.5hp | 0.5hp | 1hp | 5hp |

| JECS-32 | 1000mm | 300×800 | 1hp | 0.5hp | 0.5hp | 2hp | 7.5hp |

| JECS-40 | 1150mm | 300×1000 | 1hp | 0.5hp | 0.5hp | 2hp | 7.5hp |

| JECS-48 | 1350mm | 300×1200 | 1hp | 0.5hp | 0.5hp | 3hp | 10hp |

| JECS-60 | 1650mm | 300×1500 | 1hp | 0.5hp | 0.5hp | 3hp | 10hp |

Applications Wise Capacity:

|

Applications

|

Capacity Per Meter Width

|

|---|---|

| Pet Flakes | 1600kg |

| Glass Cullet | 10 Tons/HR |

| Wood Chip | 5 Tons/HR |

| Beverage Cains | 3 Ton/HR |

| Rubber Scrap | 800 KG/HR |

| Aluminium Scrap | 2 Tons/HR |

Salient Features:

- Tensile structure with a very stable foundation

- Zero loss of valuable material.

- Low on maintenance.

- Quality deliverance and protection for further equipment

- High yields of non-ferrous metals recovery.

Applications:

- 98% recovery of aluminum cans from commingled recyclables.

- Stainless steel, copper, aluminum, brass from shredder residue and fluff.

- Non-ferrous metal recovery in refuse streams and ash streams in Waste-to-Energy facilities.

- Separation of non-ferrous chips.

- Aluminum scrap recovery in foundry sand reclamation.

- Glass cullet recycling.

- Wood waste processing.

- Aluminum extrusion recycling.

Installed Eddy Current Separator:

Our Eddy Current Separator is used for:

- Eddy Current Separator is used for Aluminium Scrap Recycling

- Eddy Current Separator is used for Rubber Scrap Recycling

- Eddy Current Separator is used for E-waste Recycling

- Eddy Current Separator is used for MSW (Municipal Solid Waste)

- Eddy Current Separator is used for Glass Collect Recycling

- Eddy Current Separator is used for Aluminium Scrap Recycling

- Eddy Current Separator is used for Pet Flakes Recycling

- Eddy Current Separator is used for Wire Scrap Recycling

- Eddy Current Separator is used for Plastic Waste Recycling

- Eddy Current Separator is used for PVC Scrap Recycling

- Eddy Current Separator is used for Zorba