The Difference Between Overband Magnetic Separator And Inline Magnetic Separator

Overview:

Though the working principles of overband magnetic separator and inline magnetic separator are very alike, there’s a canyon difference in their purpose & functionality.

This particular blog is especially devised to differentiate between these products and give you(the readers) an understanding of what would be the equitable choice for your needs.

The facts, articles & illustrations regarding this topic will be at show too.

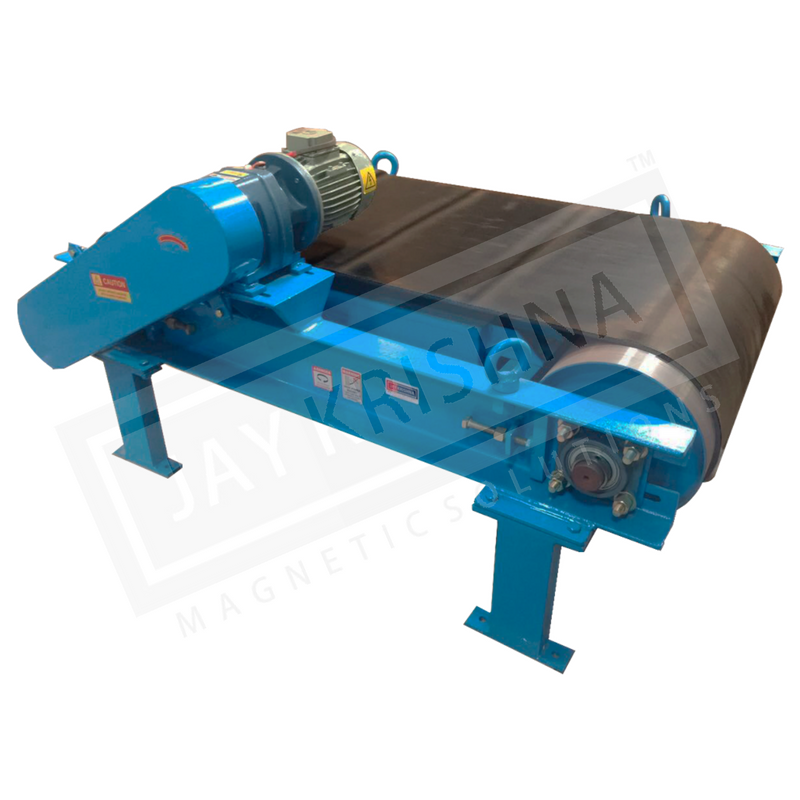

What is an OBMS (Overband Magnetic Separator)?

An overband magnetic separator is a suspension magnet with a tramp belt that is attached to a motor, adjoined to a motor revolving the belt. It’s majorly used when an automatic removal of ferrous contamination is necessary.

It’s majorly used to eliminate tramp metal from the products, vibratory feeders, inclined planes or just to protect machines such as crushers & shredders & Industries like Foundries, Coal Mines, Cement Works, Food, Sponge Iron, Charcoal, Glass, Chemical Industries and Domestic waste recycling Plants have a major use for this product.

Application & Working:

While choosing the type overband there are few parameters which have to be extracted like the speed of the belt, the nature of the product, its density, its granulometry and the size of the pieces.

The Magnet is made of High-Intensity Strontium Ferrite / Rare Earth Magnets and is guaranteed for the Magnetic Power throughout the life of the installation. A Non – Magnetic Stainless steel Plate is provided to cover the poles of Magnet. There is no need for any electrical supply or maintenance.

- The speed of the belt , the nature of the product, its density, its granulometry and the size of the pieces which have to be extracted are one of the parameters to be taken into consideration when choosing the type of Overband.

- Five types of Separators Redesigned to operate at a predetermined working gap over the conveyor : 100, 150, 200, 250 and 300mm.

- 100mm

- 150mm

- 200mm

- 250mm

- 300mm

What is Inline/Drum Magnetic Separator:

An Inline magnetic separator incorporates high-intensity strontium/rare earth magnets in a drum type closed formation that is connected to production lines such as the outlet of elevator or screw conveyor in major applications for the removal of ferrous waste from the products. These are widely used for cattle feed plants, flour mills, rice mills, minerals extractions, refractories, glass cleaning and many other products.

There are a numerous amount of modifications in the fabrication materials and even the number of drums to increase the intensity of cleaning.

Working Principle And Magnetic System:

Permanent Magnetic Drum consists of a stationary permanent magnetic assembly having a uniform and everlasting magnetic field across the entire width of the drum, which is more effective over approximately half the drum circumferences.

The Drum shell is made up of nonmagnetic stainless steel which revolves around the inner magnet. As the material fed evenly from the chute falls over the drum, a powerful magnetic field attracts & holds ferrous particles to the revolving shell & as the revolving shell carries the iron particles through the stationary magnetic field, the nonmagnetic material falls freely from the shell while ferrous particles are firmly held until carried beyond divider and out through the magnetic material chute.

Size Ranges:

The larger the diameter and width of the drum the greater is the volume of material which can be handled. The Permanent Drum Separators are available in standard drum diameters of 300mm, 400mm, 450mm, 500mm, 600mm, 900mm, 1200mm and Drum width range from 300mm to 2000mm. There are also many other sizes which are only manufactured as per special requirements.

Conclusion:

Now that you have all the required information regarding both of these material-flow connected machines, let us tell you about Jaykrishna Magnetics Pvt. Ltd., the master of magnetics, vibratory equipment, electromagnetic separators & mineral processing lines in India since 1978. They are the ones that have efficiently devised ways to separate contaminations in some of the most versatile ways in the industry and these 2 machines are no less. Call us today or email us at info@jkmagnetic.com where our team of highly qualified experts have an understanding of analyzing the perfect machine for your separation needs.

- What Is PET Recycling & How Eddy Current Separator Plays An Important Role In Metal Separation

- Lithium-Ion Battery Shredded Scrap Separation By Eddy Current Separator – A Definitive Guide

- Magnetic Separators For Detecting Impurities In Food Processing

- Why Quality Magnetic Destoner Matters in Food Processing Lines?

- 5 Most Useful Magnetic Separator For Food Processing Industry