Zorba Non-Ferrous Metal Separation Installed Line – A Detailed Guide

ZORBA is a grade of aluminum i.e softer than normal aluminum & is mainly acquired from the scrapping of vehicles and automobiles. Jaykrishna Magnetics Pvt. Ltd. has been a pioneer for the recycling industry since 1978. We have developed a highly specialized production line that fulfills entire requirements from full material separation to even micro dust residue. This line is specially customized by our highly-trained Jaykrishna Magnetics plan designing strategist. Firstly we work on factors like; knowing the requirements of the flow line, examination of the material & the parts of separation needed to be done.

Then the majority of Zorba recycling lines consists of 4 sections:

1. The Hopper:

A high capacity stainless-steel constructed hopper is provided in the line with 2 high horsepower vibratory motors. This hopper is responsible for the regulation of flow in the process and also controls the number of materials added to the next process.

2. Conveyor Delts:

The entire process revolves around this equipment, as there are 3 of them in it. It plays a mammoth role in the transportation of flow materials from one machine to another and keeps the line moving. Multiple conveyors are provided and the speed can also be modified manually.

3. Magnetic Drum:

A high capacity magnetic drum is used to separate the earthly ferrous / magnetic materials that come before in the flow line as contaminations. This machine possesses a high-standard technology used to remove about 99% of contaminations from your material flow line and make it cleaner for further operations.

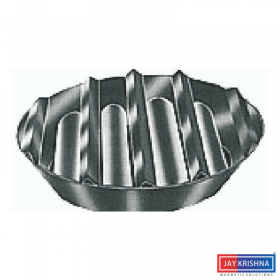

4. Density Ring Separator:

This machine is basically a giant cylinder that is connected to a single shaft high torque motor. This cylinder has different sized(in mm) holes as per the requirements of material. This cylinder when the marial reaches inside, rotates in a clockwise direction resulting in a density separation of flow lines according to their sizes. This process is really important as it can easily manipulate the particle sizes and give a more refined and finished product.

5. Eddy current separator:

The last and probably the most important machinery in the entire line, the eddy current separator is the all mighty heavyweight that separates all the non-ferrous zorba from the contaminations like plastic and silicon. This machine uses eddy current effect i.e generated by our state-of-the-art eddy-current rotor, which bounces the aluminum particles off through repulsive force. This machine is fully capable of taking on heavy loads and fast flows and we at Jaykrishna Magnetics Pvt. Ltd. are the manufacturers of this technology on a global scale.

Conclusion

Now this process might seem pretty simple, but it is a long complex process and requires some real hefty work. Adjustments and positioning of all these equipment for a steady and smooth separation is a mandatory.

Jaykrishna Magnetics Pvt. Ltd. has been the industry leader in the field of recycling for over a decade now and over the years, we have specialized in making complex things much more simpler and efficient for our customers. For more information on zorba cleaning and separation line, contact us at info@jkmagnetic.com or contact us at: +91 9825326078, +91 93274 46310

- How do Electromagnetic Vibratory Feeders Work? – Components & Principles

- What Is PET Recycling & How Eddy Current Separator Plays An Important Role In Metal Separation

- Lithium-Ion Battery Shredded Scrap Separation By Eddy Current Separator – A Definitive Guide

- Magnetic Separators For Detecting Impurities In Food Processing

- Why Quality Magnetic Destoner Matters in Food Processing Lines?