Top 8 Magnetic Separators For Industries In Sri Lanka – A Definitive Guide

With the rise of rapid urbanisation among each sector, industrial tools and equipment are crucial to combat the rising demands. Through the means of robust and advanced machineries, much large-scale industries have contributed to the upliftment of global industrialisation. Precisely talking about the magnetic separators’ industrial application, the need of conducting a thorough segregation process have risen to more than ever. Complying with the surging demands of magnetic separators, different machines have come up in the market to deal in various industries and thus, procure a fruitful product.

In the recent years, Sri Lanka has tightened its grip on elevating the industrialisation and making longer strides in the global trading market. To tackle this humongous demand of industrial growth, the magnetic separators of different kinds are required in their multiple industries. The country is fond of mineral extraction, excavation and mining and much heavily involved in exporting the minerals to abroad. This has complied to a much larger share of entire economy. In the later process, these products are enabled to refining the ferrous impurities from the grains. Since many decades, Sri Lanka has planned to peak its economy through the industrial sector, both in private as well as public, to strengthen their economic base. From food & caffeine processing industries to rubber & plastic industries, the country is phenomenal in putting astounding numeral stats.

In order to lay a profound base of smooth functioning of the mentioned industries and plants, a broad list of effectual magnetic separators have been briefed along with their vivid industrial usages. A perfect type for each sector in industrial aspect.

1. Magnetic Destoner:

This magnetic separator is extensively used for the removal of heavy impurities like metal, glass pieces, stone, mud balls and other impurities. The machine works on a specialised combination of fluidisation and deck oscillation which separates the heavy impurities from the useful substances in the outlets. Being an efficient, high-gradient and durable machine, it is majorly used in a variety of industrial applications including food grains processing & cleaning plants, ferrous-impurities remover plants, auto-cleansing machines and more.

2. Eddy Current Separator:

In the recent years the global market has witnessed a substantial growth of recycling industries and have been stressing to develop the best product out of the waste. Eddy Current Separator is the most used machine for separating the non-ferrous metals like aluminium from the on-going stream of mixture. Of all the prominent sectors, this separator makes a distinguished usage in the plastic & rubber industries to extract the beneficial ferrous objects from the pit.

3. Rotary Magnet:

Specially designed to remove ferrous particles as microscopic as 500 to 540 microns, enabling the large-scale grates to avoid any sort of clogging or damping. The powerful magnetised bars lead to a smooth flow of material so that a thorough segregation process is undertaken. With a robust construction of three-staged Rotary, it can track much smaller contaminants & dusty from the flow of materials. Along with this, the rate of feed, conveyor belt and magnetic speed can be amended through customisation. A best fit for the large-scale industries.

4. Drawer Magnet:

This is the most versatile and compact machine which can be fitted in the outlet of several equipment including blenders, classifier & pulveriser. The Drawer Magnet serves a distinguishable grid for the special operations to perform. These magnetic grids consist of magnetic rods which rotates at a given pace to separate the ferrous metals from the non-ferrous. It is because of these magnetic rods made out of hard ferrite ceramic or high rare earth magnet, which yields the magnetic strength during the separation.

5. Magnetic Grill:

Unique kind of grills which aids in refining the paramagnetic impurities from the pit. The bag full of mixed material is poured in the equipment, in which the ferrous impurities will be stuck over the magnetic grills while, the non-ferrous parts will be collected at the outlet. Thus, ensuring no ferrous impurities are passed through the grills. These are available in square as well as circle shapes. Maintaining a high-standard of protection and safety during the procedure.

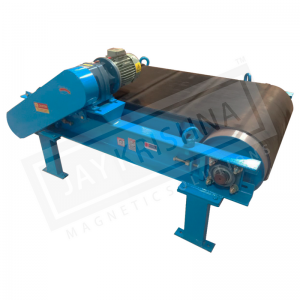

6. Overband Magnetic Separator:

With usage of permanent magnet being suspended in the overband magnetic separator, it protects the primary machines by removing the paramagnetic impurities and hence, purify the products. In this regard, the tramp metal is thoroughly eliminated from the product being carried by the vibratory feeder.

7. Hopper Magnet:

Another useful and commendable separator to separate the ferrous contaminants like nails, nuts and screws. Primarily, Hopper Magnet is an excellent equipment to protect other machines from the friction created by small ferrous tools. In total, there 4 standard sizes in square and round shapes. The separation takes place through the magnetic rods fitted on the mouth of the Hopper Magnet. Thus, ensuring no ferrous particles enter the machine. Special sizes are available for customisation.

8. Wet Drum Magnetic Separator:

This separator is one of a kind, allowing it to remove very fine ferrous impurities from very low concentrated fluids. Mainly, this equipment is utilised in the metal industries in order to treat the extracted concentrates from very high gradient magnetic filter. Enabling to remove up to 90% of ferrous fine particles in the range of 1 micrometre to 1000 micrometres. The wet drums assist in recovering the metals and simultaneously removes the contaminant for a successful separation. Ensuring product purity and efficiency of the plant altogether.

Final Thoughts

Jaykrishna Magnetics Pvt. Ltd. has always been a prominent production house of effectual magnetic separators and vibratory feeders. From serving our robust separators to partnering with our overseas clients, we are committed to serve a profound link among our customers and deliverables of quality product. Moreover, it is our professional and dedicated union of skilled members who put in real efforts in constructing & assembling the massive machineries. Along with this, we are heavily involved in providing customised products for Sri Lankan industries.

On top of this, our products are open to all sort of industries under any weather condition. We have been supplying relevant and appropriate product ranges to our clients in Sri Lanka to meet their industrial requirements.

- Best Aluminium Recycling Machinery – To Manage Streamline Process

- An Overview Of Aluminium Recycling Line Installed At Client’s Place

- How To Sort & Eliminate Aluminium Using Eddy Current Separator

- Eddy Current Separator & Overband Magnetic Separator for Glass Cullet Recycling

- Separators & Feeding Equipment’s For Recycling Industries