Separators & Feeding Equipment’s For Recycling Industries

With the growing recycling industries, the world focuses on how to use waste material to improve the standard of a living environment. Through the separation process in recycling industries, we can reuse materials such as paper, plastics, rubber, glass, bottles, metals, etc.

Recycling of waste material does not only improve the living environment but also help to reduce the significant amount of garbage. But these rapidly growing industries required highly efficient separation equipment. With the year’s experience, Jaykrishna Magnetics Pvt. Ltd. has developed the most advanced magnetic separator and vibratory machine for recycling industries.

Our separation and feeding equipment for recycling facilities:

- Shredder

- Vibratory feeder

- Overband Magnetic Separator(OBMS)

- Vibrating screening machine

- ECS

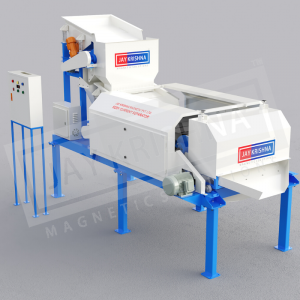

Shredder:

A shredder is a machine or equipment used to reduce the size of a given material. Shredders specially designed to support material reduction across different recycling applications, which include recycling of plastic, scrap metal, e-waste, tire, wood, glass, bottles, etc. Shredder produces the raw material that can use in the manufacturing process of numerous industrial applications. Shredding is the first step in recycling industry to recycle waste material into raw material.

Vibratory Feeder:

Jaykrishna Magnetics Pvt. Ltd. is a leading manufacturer of vibration motor base Vibratory Feeders, which utilize the forces set up by two synchronized counter-rotating, heavy duty vibrator motors. Two points in each complete revolution, the centrifugal forces of each vibrator, coincide, resulting in a linear force.

Our feeders are custom built to meet any application needed. Feeders built rugged to produce the consistent flow rates and trouble-free operation required for efficient processing. The Feeder can be designed Base Mounted or Suspension / Hanging Type.

Vibrating feeders used to handle bulk materials across all the recycling industries including plastic, scrap metal, e-waste, tire, wood, glass, bottles, etc. Products can move more quickly through the production with the help of our highly efficient vibrating feeders.

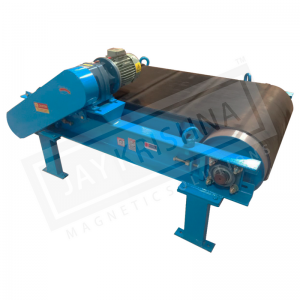

Overband Magnetic Separator (OBMS):

Jaykrishna Magnetics Pvt. Ltd. manufactures suspended permanent magnetic overband separators designed to eliminate tramp metal from the product carried by a belt, vibratory feeders, or by inclined planes in recycling plants.

Overband magnetic separators mainly used to remove ferrous particles and purify waste material. Permanent magnetic overband separators used when an automatic removal of ferrous contamination is necessary for recycling industries.

Vibrating Screening Machine:

The vibrating screening machine designed for use in the sizing of waste material in recycling industries. The unit is more than “Just a screen” it is a precision tool for producing final grades, a not merely rough grouping of sizes. It is economical of power and space; screen life is long; upkeep low.

Flexible in its adaptability to widely different materials and conditions, it is unyielding in the uniformity of grades produced. Multi-Deck vibrating screens are available in various models.

Eddy Current Separator (ECS):

Jaykrishna Magnetics Pvt. Ltd. is a leading manufacturer of Eddy current separator for different industrial applications. We are experts in developing the most efficient eddy current separator for recycling industries.

Our most advanced Eddy Current Separator magnetic separators commonly used to separate non-ferrous metals from mixed waste and other streams. It purely separates aluminum, copper, brass and other non-ferrous metals from your product stream, municipal solid waste recycling, scrap residue, and other recyclables.

In our Eddy current separator we used highly efficient magnetic drum pulley, vibratory feeder, and magnetic rotor for the better efficiency in various recycling industries.

Why Jaykrishna Magnetics Pvt. Ltd.?

From the year 1978, we are developing highly efficient magnetic separators and vibratory equipment for numerous industrial applications. Our expert engineering team has vast experience, modern machinery, and advanced technology to develop our products, which can able to perform in a robust environment with high efficiency in different industrial applications.

Read More:

- Magnetic Separator, Material Handling & Metal Detection For Recycling Industries

- Eddy Current Separator With Double Vibratory Feeder – To Boost The Yield Of Performance

- Heavy Duty Eddy Current Separators – Ready For Dispatch

- Magnetic Separators For Recycling & Sorting – The Ultimate Guide

- Eddy Current Separators – For Glass Processing Plants [Installed Machine]

Neue Tools aus revolutionären Technologien wie der 5G-Technologie, der künstlichen Intelligenz und dem Internet der medizinischen Dinge werden die Transformation des Gesundheitsplans entscheidend ermöglichen. Patienten können online einkaufen und erhalten bei sich zu Hause Treir-Bestellungen. Die persönliche Interaktion mit einem Arzt ist eine bevorzugte Situation für den Kauf von Medikamenten, aber legitime Online-Dienste bieten möglicherweise mehr Komfort. Das Internet hat bereits ganze Branchen auf der ganzen Welt aufgewühlt. Medikamente sind keine Ausnahme, und Internetapotheken haben in den letzten Jahren auf ein digitales Format umgestellt. Nicht alle Internet-Drogerien sind gleich, viele führen gefälschte Produkte oder Produkte, die von Dritten gekauft wurden. Es ist nicht immer einfach, die hoch angesehenen Websites von den “schlechten” zu trennen. Diese Online-Drogerien verkaufen häufig nicht genehmigte oder gefälschte Arzneimittel außerhalb der Sicherheitsvorkehrungen, gefolgt von hoch angesehenen Unternehmen. Die Kosten für Medikamente sind ein entscheidender Faktor für Patienten, da Produkte, die in lizenzierten Drogerien verkauft werden, für viele zu teuer sind. Überall tauchen gefälschte Heilmittel und Medizinprodukte auf. Am stärksten betroffen ist Afrika, insbesondere mit Impfstoffen, aber auch die legitimen Lieferketten in Europa sind gefährdet. Das Problem der illegalen Medikamente in der Lieferkette ist ein großes Problem, das die Industrie Milliarden kostet. Im Falle von Medikamenten wird der Patient betrogen, weil er ignoriert, dass das bestellte Produkt betrügerisch und so gesundheitsschädlich sein kann. Der Importeur oder Verbraucher des Arzneimittels ist nur für alle Risiken verantwortlich, die mit dem Handel mit gefälschten Arzneimitteln verbunden sind. Deshalb sollte eine Person, bevor sie sich für die Nutzung eines Dienstes entscheidet, aufmerksam überlegen, wie sich dies auf ihr Leben auswirkt. In unserem Tutorial erfahren Sie, wie Sie eine bessere Auswahl für Sie und Ihre Kinder treffen können. Bedingungslos levitra kaufen oder andere Medikamente, die von der virtuellen Apotheke angeboten werden, sind äußerst einfach.

Was sind die besten Generika?

klicke

Obwohl einige Mittel auf ähnliche Weise wirken, hat jedes Medikament eine leicht unterschiedliche chemische Zusammensetzung. Ihr Arzt wird viele Faktoren sowie mögliche Wechselwirkungen mit anderen Medikamenten, die Sie einnehmen, berücksichtigen. Viele Arzneimittel mit demselben Wirkstoff sind in unterschiedlichen Stärken erhältlich. Wenn es Gruppen von Rezepten gibt, die alle ähnliche Aufgaben erfüllen, sind sie bei der Behandlung einer bestimmten Krankheit ungefähr so wirksam wie die anderen. Sie können zwar Geld sparen, indem Sie günstigere Produkte nehmen, dies ist jedoch nicht immer eine gute Idee. Die Ärzte sind darin geschult, wie Sie sicher Abhilfe schaffen können. Gegenwärtig gibt es verschiedene Optionen für viagra generika für diejenigen, die an einem solchen Gesundheitsproblem leiden. Verbraucher können nützliche Informationen dazu aus evidenzbasierten Quellen wie dem Internet, den sozialen Netzwerken und sogar der Familie finden. Wissen Sie, was für Sie am besten ist? Dies ist ein Mittel zur Behandlung zahlreicher Infektionen. Was muss noch besprochen werden? Wo finden Sie korrekte Informationen dazu?

Was denkst du ist es? Es ist eine andere Frage, die wir diskutieren sollten. Die Forscher fanden heraus, dass der Missbrauch von verschreibungspflichtigen Medikamenten unerwünschte Nebenwirkungen haben kann. Heilmittel können bei manchen Menschen gefährliche Nebenwirkungen verursachen. Unerwünschte Ereignisse können bei jedem Arzneimittel auftreten. Das Arzneimittel sollte nicht zusammen mit anderen ED-Behandlungen eingenommen werden, da die Sicherheit solcher Kombinationen nicht nachgewiesen wurde. Befolgen Sie unbedingt die Empfehlungen Ihres Arztes, einschließlich der vorgeschriebenen Einnahme der verschriebenen Mittel. Dieser Rat ist üblich, kann jedoch den Unterschied ausmachen, wenn Sie Informationen zu Arzneimitteln benötigen. Wie auch immer, die Umstände, die Ihre Entscheidung vorbestimmen können, können unterschiedlich sein. Dies sind wichtige Möglichkeiten, um sich um Ihren Körper zu kümmern, an die Sie möglicherweise nicht von Natur aus denken. Wenn Sie sich jedoch Ziele setzen, um diese Ideen in Ihrem Leben Wirklichkeit werden zu lassen, werden Sie den Unterschied sofort spüren, aber in den kommenden Monaten auch in mehreren Bereichen Ihres Lebens Ergebnisse sehen.

du könntest hier schauen

{Wie kaufe ich cialis generika?

Medikamente könnten Teil Ihrer täglichen Routine sein, um Ihre Gesundheit gut zu verwalten. Internet-Drogerien kombinieren garantiert niedrige Preise mit schnellem Versand. Wenn es darum geht, privat verschriebene Medikamente zu kaufen, bieten Ihnen Online-Drogerien mehr Auswahl beim Eingang Ihrer Bestellung. Da immer mehr Patienten online gehen, um ihre Gesundheitsprobleme zu verstehen, gehen einige auch online, um generische Mittel zu kaufen. Natürlich sollte jeder von uns Zugang zu wichtigen und kostengünstigen Mitteln haben, die zur Bekämpfung von Infektionen beitragen oder einfach die allgemeine Gesundheit verbessern. Der Online-Kauf von Generika kann eine gute Idee sein, solange Sie dies verantwortungsbewusst tun. Zugegeben, sobald das Generikum verfügbar ist, werden die Kosten sowohl für das ursprüngliche Markenprodukt als auch für das Generikum erheblich gesenkt. Sie haben sie natürlich im Supermarkt gesehen. Generische Versionen von Arzneimitteln sind in vielen ausländischen Märkten, einschließlich Kanada und den meisten Ländern Europas, legal. Generika sind grundsätzlich nur deshalb billiger, weil die Hersteller nicht die Kosten für die Entwicklung eines neuen Arzneimittels hatten. Generika sind im Allgemeinen etwas günstiger und meist genauso wirksam wie Markenmedikamente. Jeder weiß, dass es wichtig ist, darüber Bescheid zu wissen.

Wenn Sie cialis generika kaufen, erkundigen Sie sich bei einem qualifizierten Gesundheitsdienstleister, ob diese unschuldig sind, wenn Sie sie mit Ihren anderen Generika einnehmen.

|Wenn Sie online über Medikamente nachdenken, möchten Sie vielleicht mehr über dieses Problem erfahren. Zweifellos haben Sie bereits etwas darüber gehört, wie man cialis generika kauft. Viele gesundheitsbezogene Websites bieten mehr Inhalte und dies könnte die Patienten zum Thema führen.

Vielleicht wissen Sie bereits etwas über das Problem. Lassen Sie uns nun über verschiedene Medikamente sprechen, die Sie online kaufen können. Es ist wichtig, über sichere Wege zum Kauf von Medikamenten informiert zu bleiben. Wenn Sie über Ihre Behandlungsoption nachdenken, kann es hilfreich sein, einige wichtige Fakten darüber zu kennen, wo Sie cialis generika kaufen können.

Diejenigen, die Rabattmedikamente und Nahrungsergänzungsmittel in Betracht ziehen, werden häufig eine Reihe von Optionen zur Auswahl finden. Es ist verlockend, Medikamente und Kräuterergänzungen online zu kaufen, wenn dieselben Produkte so viel billiger sind. Vieles, was darüber gesagt wurde, gilt auch für natürliche Gesundheits- und Wellnessprodukte und alltägliche wichtige Toilettenartikel. Wenn Sie cialis generika kaufen, sollten Sie einige wesentliche Details kennen.

|Wenn Sie die Anziehungskraft auf einen bestimmten Partner verloren haben, ist es normalerweise unwahrscheinlich, dass Behandlungsoptionen zur Verbesserung der Potenz ihm helfen. Als die Mehrheit der Einzelhändler online ging, stiegen die Erwartungen und eine überwältigende Anzahl von Kunden erwartete, online die Mittel zu finden, die sie benötigen. Illegale Online-Apotheken versuchen möglicherweise, illegale “generische” Versionen dieser Originalmarkenmedikamente zu verkaufen. Fragen Sie Ihren Apotheker nach Informationen, wenn Sie sich über den Online-Kauf von Generika nicht sicher sind. Darüber hinaus machen Generika die überwiegende Mehrheit der landesweit verschriebenen Rezepte aus. Das Medikament ist verschreibungspflichtig und muss unter Aufsicht eines Arztes angewendet werden. Aber ist es wirklich das richtige Feld für Sie, cialis generika zu kaufen? Es gibt verschiedene ernsthafte Fragen zu diesem Thema. Darüber hinaus kann es auch zur Behandlung einiger anderer von Ihrem Arzt festgelegter Erkrankungen verwendet werden. Wenn Sie sicher sind, dass diese gesetzlichen Anforderungen erfüllt werden können und Sie wissen, dass die von Ihnen ausgewählte Apotheke sicher ist, ist es möglicherweise an der Zeit, Ihre verschreibungspflichtigen Medikamente aus einer Online-Apotheke zu beziehen. Während sich alle Symptome bessern können, bevor die Krankheit vollständig behandelt ist, nehmen Sie das Mittel für den gesamten vorgeschriebenen Zeitraum ein. Auf dieser Website finden Sie einige nützliche Informationen zu den Risiken von Arzneimitteln und deren Erforschung.

Was ist ein kostengünstiges Medikament, um Patienten bei der Aufrechterhaltung einer Erektion zu helfen? Der Rat ist unkompliziert, kann aber den Unterschied ausmachen, wenn Sie Informationen zu diesem Thema benötigen. Obwohl der Missbrauch verschreibungspflichtiger Medikamente viele Familien betrifft, können bestimmte Bevölkerungsgruppen wie Jugendliche einem besonderen Risiko ausgesetzt sein. Für die meisten Menschen, die keine Erektion bekommen, die fest genug für Sex ist, funktionieren Arzneimittel gut, verursachen aber manchmal schwerwiegende Nebenwirkungen. Und die Pillen gelten allgemein als sehr sicher. Häufige unerwünschte Effekte können das sogenannte blaue Sehen sein, aber es ist sicherlich häufiger, wenn Sie mehr als die vorgeschriebene Menge einnehmen. Sie können eine Checkliste für Nebenwirkungen verwenden, um den Überblick zu behalten und Informationen schnell mit Ihrem medizinischen Fachpersonal zu teilen. Nehmen Sie dieses Generikum nicht in kleineren Mengen ein. Der Rat ist üblich, kann aber den Unterschied ausmachen, wenn Sie Informationen über Pillen benötigen. Normalerweise erfordert die Behandlung Geduld, um eine erwartbare Wirkung zu erzielen. Verbraucher sollten die online gefundenen Informationen jedoch immer objektiv behandeln. Schließlich können Sie Zeit bei Ihren Rabattmedikamenten und Kräutern sparen, indem Sie sie online bestellen.}

Überprüfen Sie meine site

{Wie cialis generika?

Der ideale Zeitpunkt für den Beginn der Behandlung ist, bevor sichtbare Anzeichen auftreten. Die zunehmende Nachfrage nach Informationen im täglichen Leben von Millionen von Menschen hat dazu geführt, dass immer mehr pharmazeutische Gesundheitsdienstleister versuchen, ihre Gesundheitsprodukte vor ihren Konkurrenten zu positionieren. Wie finde ich Medikamente online? Die Verschreibung und Verwendung von Medikamenten ist jedoch Vertrauenssache. Für Kunden wird es immer einfacher, Medikamente online zu bekommen. Es gibt viele Online-Apotheken im Internet, daher sollte es kein Problem sein, eine vertrauenswürdige Drogerie zu finden. Sie bieten Kunden mit eingeschränkter Mobilität und Kunden in abgelegenen Gebieten Zugang. Die reduzierten Transaktionskosten werden in Form weitaus niedrigerer Preise an die Patienten weitergegeben. In beiden Fällen ist es nicht alles. Dieser Leitfaden behandelt alles von der Sicherung Ihres Computers bis zur Überprüfung und Bestellung von Viagra in zuverlässigen Online-Apotheken.

10 Möglichkeiten, gefälschte Medikamente zu erkennen.

|Deshalb interessieren sich viele für dieses Thema. Ist es für Sie aktuell, wie man cialis generika?

Lassen Sie uns Antworten auf Ihre wichtigsten Fragen zu diesem Thema finden. Das Bestellen von Rezepten im Internet kann eine kostengünstige Methode sein, solange Sie dies verantwortungsbewusst tun. Lassen Sie uns darüber sprechen, wie Sie sicher sein können, dass online bestellte Medikamente den Qualitätsstandards entsprechen. Ziemlich cialis generika oder andere Medikamente, die von einer virtuellen Drogerie angeboten werden, sind sehr elementar.

Es gibt viele gültige Internet-Drogerien, die legitime Rabatte anbieten. Wenn Sie Medikamente online kaufen möchten, tun Sie dies in einer legalen Apotheke. Die Lieferanten bieten Tausende von Arzneimitteln an, zu denen sowohl generische als auch bekannte Marken gehören. Es gibt Varianten von renommierten virtuellen Drogerien, in denen Patienten Viagra bestellen können.

|Zu wissen, wonach zu suchen ist, kann eine Herausforderung sein, insbesondere bei allen verfügbaren Optionen. Normalerweise sind viele Medikamente zu berücksichtigen. Können Sie verschreibungspflichtige Medikamente legal online bekommen? Es ist wichtig, die Vorteile verschriebener Medikamente sowie deren mögliche unerwünschte Wirkungen zu kennen und mit Ihrem Apotheker über mögliche Bedenken zu sprechen. Wenn Sie besprechen, wie Sie Viagra bestellen können, ist es viel wahrscheinlicher, dass Sie einen Plan entwickeln, der für Sie gut funktioniert. Wir alle können verlässliche Informationen aus vertrauenswürdigen Quellen wie dem Internet, den Medien und sogar Freunden finden. Dies sind sicherlich nur die Grundregeln. Wenn Sie Arzneimittel bestellen, sollten Sie darüber nachdenken. Seit Jahrzehnten helfen diese Medikamente, viele Störungen zu verhindern. Der ideale Zeitpunkt für den Beginn der Behandlung ist, wenn nur Symptome auftreten. Themen zur Bestellung von Viagra sind im letzten Jahr sehr beliebt. Einige Forscher achten auf solche Angelegenheiten. Haben Sie etwas über Nebenwirkungen gelernt?

Höchstwahrscheinlich hat jeder Mann zumindest etwas davon gehört. Wenn Sie Medikamente in Online-Apotheken bestellen möchten, erhalten Sie normalerweise zuerst ein gültiges Rezept. Es ist wichtig zu verstehen, dass nicht alle Medikamente wirklich nützlich sind. Wie alle Arzneimittel hat das Arzneimittel unterschiedliche unerwünschte Wirkungen. Informieren Sie Ihren Arzt, wenn Sie andere Arzneimittel einnehmen. Ihre Medikamente sind nur für Sie. Geben Sie es niemals an andere Personen weiter, auch wenn ihr Zustand mit Ihrem identisch zu sein scheint. Letztendlich sind diese Faktoren auf der ganzen Welt gleich. Wenn Sie diese Tipps befolgen, sollten Sie bereit sein. Darüber hinaus ist das Internet die geeignete Möglichkeit, um alle Arten von Arzneimitteln zu erwerben, da es das Vergnügen bietet, sich über das Internet zu bewerben.}