Magnetic Separators for Food, Recycling & Plastic Industries In UAE

In our contemporary world, providing safe and secured products has been an eminent process to the clients and their offices. Procuring the best essence out of the dump has been a necessary act in ample of industrial sectors. Being able to conduct the refining process is more like a mammoth task if carried out traditionally. Fortunately, the task can be undertaken by the magnetic separators smoothly and efficiently in all the prominent sectors.

Magnetic Separators have certainly raised the bar of safety standards in food as well as yielding a 100% pure material devoid of metallic impurities in the processing lines. Not only has it reduced the labour work, but gained a surplus quality product at an efficient rate. Our daily products often went unnoticed but the work laid in to bear out the pure beneficial product is mainly due to the magnetic separators. Immensely grateful to the advanced innovations taking place in the scientific field to upgrade the existing design of magnetic separators and make it even better and faster than ever. Interestingly, the notable industrialists of UAE have geared themselves up to make the maximum application of magnetic separators in the prominent sectors like, plastics, textile, oil, recycling, powder, food & grain, chemical and more.

With this being said, the following are some of the most effective and versatile magnetic separators being utilised in various industries. Each separator has a distinguished purpose to serve in the field.

1. Magnetic Destoner:

As the name suggests, Magnetic Destoner is extensively used for the removal of heavy impurities like metal, glass pieces, stone, mud balls and other impurities. The machine works on a specialised combination of fluidisation and deck oscillation which separates the heavy impurities from the useful substances in the outlets. Being an efficient, high-gradient and durable machine, it is majorly used in a variety of industrial applications including food grains processing & cleaning plants, ferrous-impurities remover plants, auto-cleansing machines and more.

2. Eddy Current Separator:

In the recent years the global market has witnessed a whopping growth of recycling industries and have been focussing to develop the best product out of the scrap metals. Eddy Current Separator is the most used machine for separating the non-ferrous metals like aluminium from the on-going stream of mixture. Of all the prominent sectors, this separator makes a distinguished usage in the recycling industries to extract the beneficial ferrous objects from the pit.

3. Drawer Magnet:

This is the most versatile and compact machine which can be fitted in the outlet of several equipment including blenders, classifier & pulveriser. The Drawer Magnet serves a distinguishable grid for the special operations to perform. These magnetic grids consist of magnetic rods which rotates at a given pace to separate the ferrous metals from the non-ferrous. It is because of these magnetic rods made out of hard ferrite ceramic or high rare earth magnet, which yields the magnetic strength during the separation.

4. Magnetic Trap:

This magnetic separator is unique in its own way. It literally traps the ferrous impurities from the liquid processing lines which are majorly used in the cooling systems. The system is built of high intensity rare earth magnets which entraps the paramagnetic particles and a fruitful material is yielded at the end-outlet. More suitable for paper, chemical, ceramic and pharmaceutical industries.

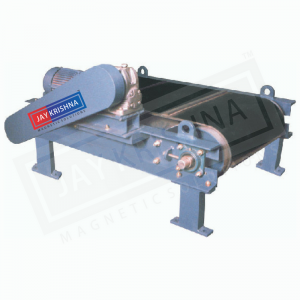

5. Overband Magnetic Separator:

With usage of permanent magnet being suspended in the overband magnetic separator, it protects the primary machines by removing the paramagnetic impurities and hence, purify the products. In this regard, the tramp metal is thoroughly eliminated from the product being carried by the vibratory feeder.

6. Hump Magnet:

A unique, vertical body of magnetic Hump assists in the intensified process to segregate the ferrous impurities from the minute food grains, powder and granules. With a hinged type doors to pour the material in, the Hump Magnet consists of two plate magnets; one at the top and another at the bottom, where the minute ferrous particles are stuck and a 100% healthy food product is collected from the end-outlet.

7. Rotary Magnet:

An ideal separator to avoid the clogging of the stationery objects and efficiently removes the foreign minute particles from the food powder as small as 500 microns to 540 microns. The slow and gradual rotation ensure no bridging of the products and the magnetic rods move through the powdered substance to increase the magnetic intensity. Thus, yielding a safe and healthy food powder devoid of any harmful, ferrous particles. Further, the Rotary Magnets are available in 120 mm, 150 mm, 200 mm and 250 mm diameter for an effectual magnetic separation of the powder.

Jaykrishna Magnetics Pvt. Ltd. has been an entrusted manufacturer of magnetic separators for a prolonged period of time, delivering the standard of excellence to their esteemed clients and their industries. Our adoption to the latest technology and advancement of the products has led us to meet the complex requirements with ease in a short time. Further, our collective union of assets with a sound knowledge about the technological advancements always assesses the products under every weather condition before dispatching them for the industrial usage.

We have emerged as the leading manufacturer of magnetic separators in the large-scale industries of plastic, recycling and food in UAE.

Read More:

- Best Aluminium Recycling Machinery – To Manage Streamline Process

- An Overview Of Aluminium Recycling Line Installed At Client’s Place

- How To Sort & Eliminate Aluminium Using Eddy Current Separator

- Eddy Current Separator & Overband Magnetic Separator for Glass Cullet Recycling

- Separators & Feeding Equipment’s For Recycling Industries