Magnetic Separator & Vibratory Feeder For Waste Rubber Tire Recycling- An Informative Guide

Introduction:

In the waste tyre recycling line, magnetic separator is the most important machinery used to remove thin steel wire and other metallic impurities from the rubber powder. Magnetic separator set apart metal and other impurities from rubber powder. This machine has transformed the whole rubber recycling industry with its high efficiency and robust design.

Globally India contributes 6 to 7 percent to the waste tyre recycling sector and because the local tyre industry increasing at 12% per annum the quantity of waste rubber is also increasing rapidly. For nearly four decades India is recycling rubber waste and today we are the second-largest recycler of waste rubber material behind china.

More than a billion numbers of tyres become scrap every year. It is expected that globally 15 million tones of the waste tyre is generated annually. Dumping such a large amount of waste into the junkyard leads to environmental crises and make the surrounding harmful. Thus by recycling waste rubber properly through magnetic separator machinery helps to overcome such problems.

Working Principle Of Magnetic Separator:

Magnetic separation machinery consists of powerful magnets which are placed on the ceiling of the machinery. Firstly the waste rubber is poured into the overband magnetic separator to remove tramp metal from the rubber, then belt conveyor conveys other non-metallic impurities to the vibratory feeder for consistent material flow. Finally after the recycling process pure rubber is collected in the outlet.

Here are the types of equipment used in rubber recycling plant:

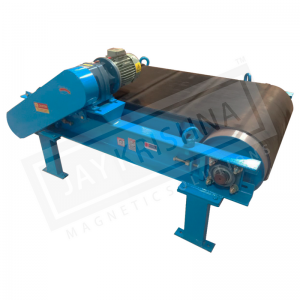

Overband Magnetic Separator:

Jaykrishna Magnetics Pvt. Ltd. manufactures suspended permanent overband magnetic separators that are designed to eliminate tramp metal from the product carried by a belt, vibratory feeders or by inclined planes.

Overbands are mainly used to protect machines such as crushers, shredders, and others, to remove ferrous particles and purify products (Industries like Foundries, Coal Mines, Cement Works, Food, Sponge Iron, Charcoal, Glass, Chemical Industries and Domestic waste recycling Plants). Permanent magnetic over band separators are used when an automatic removal of ferrous contamination is necessary. If not then fixed permanent suspension magnets are more preferable.

Salient Features :

- Used in either ceramic or powerful rare earth magnet.

- Separator body covering.

- Low maintenance

- Roughest construction

- High efficiency of separation

- Long belt life

Conveyor Belt :

Belt conveyor is one of the carryings or transporting mechanisms of recycling materials. Depending on the recycling materials’ complexity, the looping belt requires robust and durable properties to resist impact, wear and leaking of oil and grease. It is used to connect various sorting stations, belts space the items so the waste can be separated manually or mechanically.

Vibratory Feeder:

Jaykrishna Magnetics Pvt. Ltd. manufactures Vibration motor base vibratory feeders, which utilize the forces set up by two synchronized counter-rotating, heavy duty vibrator motors. Two points in each complete revolution, the centrifugal forces of each vibrator coincide, resulting in a linear force.

Our feeders are custom built to meet any application needed. Feeders are built rugged to produce the consistent flow rates and trouble-free operation needed for efficient processing. The Feeder can be designed either Base Mounted or Suspension / Hanging Type.

Our vibratory feeder is used mostly for material handling in various industrial applications. We have used highly efficient vibratory motors for the desired results.

Technical Specifications :

- The Mechanical Vibratory Feeder consists of a tray made out of Mild Steel.

- The body housing of the Vibrator is made from Heavy duty M.S.Plates.

- As the Motor get energized the Vibration sets the material in motion.

- The Vibration of the feeder will be controlled with the help of adjusting loads of the motor.

- The Feeder will be mounted on Heavy Duty Spring Bar/Brackets or Base Mounting.

At Jaykrishna Magnetics Pvt. Ltd., we manufacture the best quality of overband magnetic separators, conveyor belt, and vibratory feeders for the various waste rubber tyre recycling industries. In the 40+ years of experience, we helped several recycling lines by supplying our range of magnetic separators and vibratory feeder for separating and conveying materials. To know more about our machines, email us your details.

Read More:

- Best Aluminium Recycling Machinery – To Manage Streamline Process

- An Overview Of Aluminium Recycling Line Installed At Client’s Place

- How To Sort & Eliminate Aluminium Using Eddy Current Separator

- Eddy Current Separator & Overband Magnetic Separator for Glass Cullet Recycling

- Separators & Feeding Equipment’s For Recycling Industries