Industrial Vibratory Motors – The Definitive Guide

Handling and storing bulk material has been a challenge for years. Different kinds of technology have been used for loading, unloading, handling and storage of various materials like granules, stones, cement, etc., as well as their mixing and homogenization. Historically, techniques such as water and air lances, silo cleanout equipment, shot gun blasts have been used to handle and to eliminate material blockage. However, lately, vibration technology, based on the principle of use of vibration as an energy vector, can be used to carry out these operations. Vibrating systems are designed to handle bulk storage and discharge all shapes and sizes of components in a controlled manner – often onto weigh scales for bagging.

Vibration phenomena can be created using electric motors equipped containing rotating masses, or through the release of pressure waves from pneumatic hammers. An electric motor vibrator is composed of two main parts:

- a motor body

- rotating masses placed at the ends of the drive shaft

The stress of a motor vibrator is generated by the centrifugal force produced by the rotating masses. The use of motor vibrators allows two kinds of vibration to be obtained:

1) Rotational

This is possible when using only one device. While using one device, the centrifugal force picks up, a different direction every moment and the structure to which it is connected, and therefore the material contained in it takes on an elliptical trajectory.

2) Directional

This is possible when using two devices with the same characteristics, rotating in opposite directions, connected rigidly to the same support. Using two motor vibrators, the centrifugal forces of the masses, which rotate in opposite directions, have the components on the rotational plane – equal but characterized by opposite direction – canceling each other out. The components, which are perpendicular to the plane – equal and characterized by the same direction – are added together and as a result, give a centrifugal constant directional force. This situation imposes a uni-directional motion on the structure connected to it.

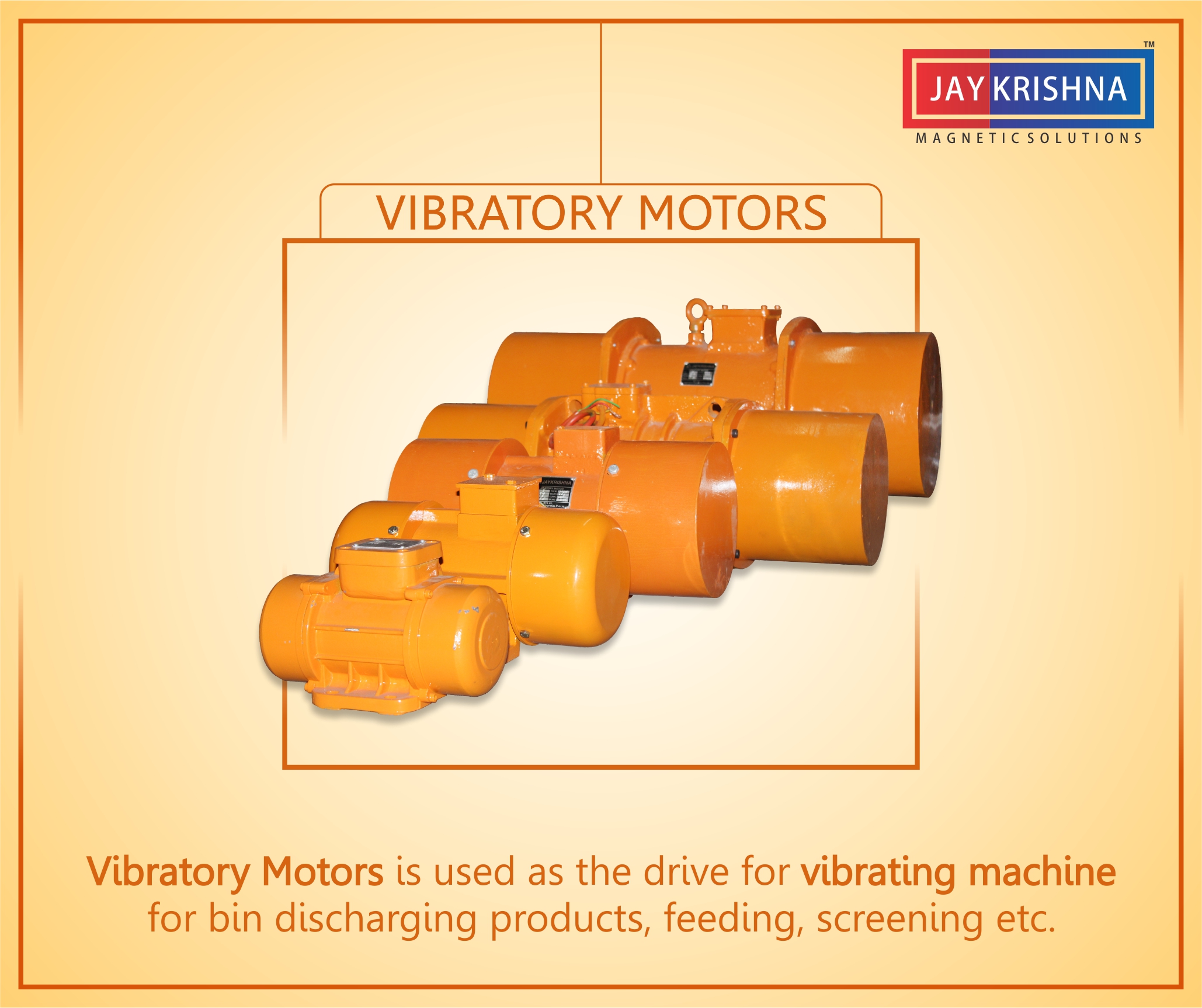

At Jaykrishna Magnetics Pvt. Ltd., we offer bulk material handling equipment. Our industrial vibratory motors are designed to increase efficiency with lower energy consumption and maintenance requirements. Having the right vibratory motors for cement blocks and cast cement components is essential for maintaining a smooth workflow with less maintenance. We offer a variety of vibratory motors for cement processing as per your requirements.

Don’t Forget To Watch Video:

Applications Of Vibratory Motors:

- Pharmaceutical Industries

- Plastic Industries

- Cement Industries

- Flour Milling

- Food Industries

- Rice Milling

- Silica Sand Processing

- Mining Industries

- Power Plants

- Petrochemical Industries

- Processing Industries

Our vibratory motors can handle the following kinds of bulk material:

- Sand

- Gravel

- Coarse and fine-crushed stone

- Cement and concrete

- Gypsum and limestone

- Brick

- Plaster

- Roofing tiles

Jaykrishna Magnetics Pvt. Ltd. has a proven track record of manufacturing and supplying premium quality of vibratory motors. If you are looking for the best vibratory motors in your industry, then feel free to contact us. Our team will get back to you with more information.

Read More: