Electromagnetic Vibratory Feeder – Informative Guide

Jaykrishna Magnetics Pvt. Ltd has developed many types of vibratory equipment in last 38 years to fulfilled the client requirements all over the world. We are well known for their best quality products and supportive services.

Seeing the demand of prominent electromagnetic vibratory feeder in the market which is also called EMVF, we developed one of the best electromagnetic vibratory feeder which is suitable to control bulk products flow in material handling plants like coke, quartz, mineral cement glass and many other application and industries. Commonly it is used for performing gravimetric flow of granular and particulate materials in process and material handling industry.

In electromagnetic vibratory feeder, the cyclic operation is just controlled by a range of electronic devices that will vary the feeding rate in a manner to suit all the applications. All of our feeders need separate controllers to control. Our electromagnetic vibratory feeder is ideally suitable for controlling the flow of bulk material to the secondary processing operation.

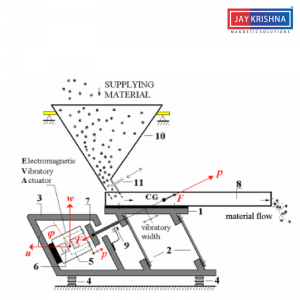

The basic construction of electromagnetic vibratory feeder is given below.

Compare to other manufacturer design our straightforward and compact construction are more reliable in operation. A driving electrical current excites the magnetic core, attracting the moving armature which is attached to the load carrying an element of the electromagnetic vibratory feeder.

Technical Specification of Electromagnet Vibratory Feeder:

- The electromagnetic vibratory feeder consists of a tray made from Mild Steel or Stainless Steel and the body housing.

- The body housing of the vibrator was made from heavy duty M.S. Plates.

- As the magnet get energised the vibration sets the material in the motion.

- The controller of vibrator gives the controlled flow of the material.

- The housing of the electromagnet was made in a totally enclosed design that make it dust proof.

Applications:

- Chemical Plants: To controlled flow of ingredients to mixing tanks.

- Foundries: For the addition of binders and sand processing systems.

- Iron and Steel Industries: the Controlled flow of iron ore, scrap and smelting furnace.

- Glass Industries: Handling glass cullet to the furnace and glass products. Also, you can use for chemical additives handling like ash, soda, etc.

- Ceramic Industries: For controlled ingredients in batch processing.

- Pulp and Paper Industries: Chemical additives feeding in batch processing.

- Metal: Feeding metal parts to heat treating furnace.

Salient Features:

- Low Noise

- Maintenance Free

- M.S or S.S feed troughs

- Robust Construction

This how our electromagnetic vibratory feeder is useful for your application with any hassle of maintenance or noise.

We are also manufacturing a particularly innovative product called Electromagnetic Vibratory Feeder with Feed Hopper as per the client requirement. Check this video