Industrial Magnetic Plates – Advanced Guide

Removal of fine ferrous material and tramp iron from various free flowing and pneumatically conveyed material in necessary to manufacture quality of product either it was any food product or any industrial plastic materials.

After the Make In India initiative, Indian manufacturing industries is all set to take place in the map of the world. While manufacturing any products to sell into the market it is the duty of every company to make sure that product is well and good to use in machines. Security of employees and quality of machines plays a major role while exporting or importing any machines.

We at Jaykrishna Magnetics Pvt. Ltd. manufactures each and every product keeping all these factors in mind. We focus on creating best machines as per the client requirement using all international standards. Delivering the value to the customer is important to us.

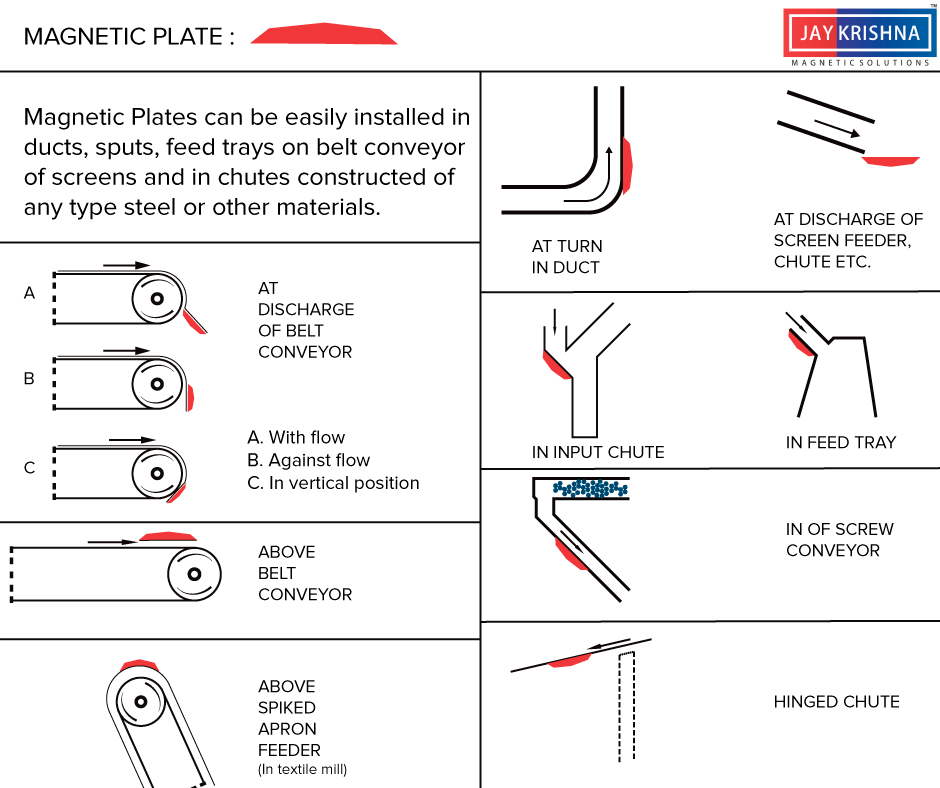

From many of our industrial magnet products, we manufacture the best magnetic plate that fulfills your each and every requirement. Magnetic Plate is one of the industrial iron separator product which can be used to remove tramp iron from the moving material carried in chutes, ducts, spouts or on conveyors belts, screen, and feed trays.

Jaykrishna Magnetics Pvt. Ltd. design industrial magnetic plates in various sizes and strengths to meet the specific operation and plant condition.

Our Permanent Magnetic Plates are designed in various sizes & strengths to meet with specific operation & plant conditions. It also separate tramp iron from pneumatically conveyed material like flour, granules, plastic, sugar, corn and many other materials. In short, they are suitable for filtering metal particles out of free-falling product streams or products on a conveyor belt with relatively small amount of Fe contamination.

We manufacture two different types of magnetic plates called flat shape and curved shape. It can be installed either above or at the discharge end of the material flow.

Working Process:

Industrial Magnetic Plates are located above the material flow. Now, what Magnetic Plates do that whenever the material flows it the attract the iron material when it passes by the plate. It will hold the tramp and unnecessary material tightly to the magnet surface until it removed during the process of cleaning. To clean material in large quantity multiple plates are used at the various different location.

Salient Features:

- Durable Stainless Steel Construction

- Easy Installation

- Low Maintenance

- Magnetic Plate consists of high coercivity modern anisotropic

- Ferrite Magnet or Rare Earth Magnet is used in magnetic plate

- Plate can be mounted on both above and below the product flow

- Customized Design

- Strong & rugged construction with M.S or S.S 304/316 construction

Applications of Industrial Magnetic Plates:

- Mineral Processing

- Pharmaceutical Industries

- Foundries

- Food Industries

- Detergents

- Cattle Feed Materials

- Fertilizer Industries

By this way, Industrial Magnetic Plates plays a major role in the separation of various minerals. If you are looking for such plates for given application click here to get a FREE Quote.