Top Magnetic Separators For C&D Waste Recycling And How They Work

Introduction

C&D waste volumes have been growing across the world. Creating valuable construction materials from this waste is crucial due to the scarcity of such materials.

Construction and demolition (C&D) waste is generated from outlived construction demolition, repair, renovation, and construction works.

Recycling industry manufacturers can help divert Tonnes of construction, demolition, and excavation waste from landfill simply by transforming C&D waste into valuable construction materials.

Advanced separation and processing systems can help easily churn out washed, recycled sand and aggregates for valuable construction applications.

For obtaining valuable construction materials from bulky and heavy demolition waste fractions, effective separation of non-ferrous metals is necessary.

Magnetic Separator for C&D waste is designed to handle heavy materials and separate non-ferrous metals.

Read on to learn the top magnetic separators that can be used for C&D waste recycling.

But before we dive into the best C&D waste recycling magnetic separator, let’s learn about C&D waste, its importance, and its benefits.

What Is C&D Waste?

Construction and demolition waste is solid waste generated from the process of construction and demolition of old buildings.

C&D waste consists of a wide variety of materials such as soil, slag, wood, brick, glass, plastic, clay tiles, concrete, metal, drywall, and other materials. Many of these materials can be repurposed and reused for construction applications.

Some components from C&D waste have high resource value while some have lower resource value, but majorly all can be easily recycled into new materials using advanced C&D recycling magnetic separators.

Why Is C&D Waste Recycling Important?

Recycling of C&D materials is important for many reasons. As stated above, it is generated from the construction, repair, renovation, and demolition of large buildings, houses, roads, bridges, piers, and dams.

Construction and demolition waste is crucial to recycle as it contains hazardous materials such as lead, solvents, and asbestos. When these materials are not separated, they can cause serious harm to the environment when dumped into landfills.

Despite this, industries are facing growing problems of contaminated soil which can be resolved by wet processing soil and separating all organic waste and contaminants like fluoride, chrome, arsenic, and PFAS from the soil, making it safe to reuse.

Another reason why C&D recycling is important is it helps divert a notable amount of waste away from landfills, which ultimately lowers the requirement of extracting new materials from the earth.

By and large, recycling C&D waste materials helps reduce environmental degradation for products.

Benefits Of C&D Waste Recycling

➡️ Reduce financial costs associated with raw materials extraction and processing

➡️ Increased production of quality and valuable recycled sand and aggregates

➡️ Ecologically meets the growing demand for sand and aggregates

➡️ Supply of sand and aggregates in areas that don’t have natural reserves availability

➡️ Reduce transportation costs generated by buying sand and aggregates and their disposal

➡️ Lower carbon footprint by recycling valuable construction materials

Best Magnetic Separators For C&D Waste Recycling

The recyclable materials of C&D waste, such as inert materials, wood, paper, metals, and plastics, are recovered using advanced sorting systems and magnetic separation techniques.

Magnetic separators such as suspension magnets are used to separate all the ferrous metals present in waste materials, such as plates, bolts, and reinforcement bars.

Further, to separate non-ferrous metals, separators like Eddy Current Separator are used to effectively separate impurities and recover valuable metals.

Jaykrishna Magnetics Pvt. Ltd. is a renowned magnetic separator manufacturer in India. We provide the best C&D waste recycling separators to effectively remove contaminants and produce sellable sand, aggregates, and other valuable materials.

Our magnetic separators can easily handle and separate stubborn contaminants like clay, metals, rubber, plastics, organics, paper, and polystyrene.

Below is the list of top magnetic separators for C&D waste recycling

1️⃣ Electro Magnetic Lifter

This is lifting equipment used to shift heavy objects from one place to another. It picks up iron pieces from the C&D waste materials and then moved them to another position, then the electromagnetic lifter is switched off, and the iron pieces are released.

2️⃣Overband Magnetic Separator

This type of magnetic separator is designed to eliminate tramp metals from the C&D waste carried by a belt or vibratory feeders. It is mainly used for the automatic removal of ferrous contamination from C&D waste materials.

3️⃣ Eddy Current Separator

This is one of the best magnetic separators used in the C&D waste recycling process. Also known as a non-ferrous separator it is used to separate nonferrous metals from C&D mixed waste. Metals like aluminum, copper, brass, and much more can be easily separated using Eddy Current Separator.

4️⃣ Suspension Magnet

Usually placed above the conveyor belt, a suspension magnet is useful for removing impurities from low-contaminated C&D materials.

5️⃣ Drum Type Magnetic Separator

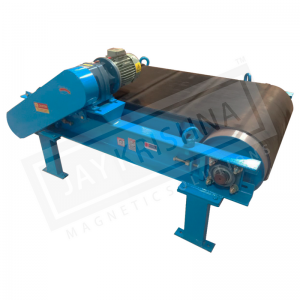

This type of magnetic separator is widely used to separate ferrous impurities from C&D waste in large quantities. It is the ideal separator for the continuous turnover of products.

Bottom Line

To ensure the reliable separation of contaminants from C&D waste, it is important to install the right magnetic separator. With quality magnetic separators recycling C&D waste will be no more difficult.

At Jaykrishna Magnetics Pvt. Ltd., we provide the best magnetic separator for the C&D waste recycling line. As every construction and demolition waste has variable nature, hence we suggest an ideal magnetic separator built according to your specific project requirements.

Get in touch with us today to get the bespoke solution for C&D waste recycling needs.

Read More:

- The 3 Best Magnetic Separators For E-Waste Recycling (WEEE)

- High-Intensity Magnetic Separators For Mining And Mineral Processing Industry

- Top Quality Magnetic Separators For Zorba Scrap Recycling Industry