Top Quality Magnetic Separators For Zorba Scrap Recycling Industry

One of the greatest challenges in the Zorba scrap recycling industry is the problem of sorting. Rarely found in a clean and purifying state, scraps are generally dirty mixtures of several types of metals rolled up together.

Durable and efficient Magnetic Separators are needed to separate ferrous and non-ferrous metals from scrap to recover valuable metals.

Hence, installing a quality magnetic separator plays an important role in recycling Zorba scrap to ensure they can be used in the smelter and achieve the maximum amount of marketable quality metal.

Read ahead to learn more about Zorba Scrap and what are the best magnetic separators to use for the Zorba Scrap recycling industry.

What Is Zorba Scrap?

Zorba is a shredded mix of non-ferrous scrap metals, primarily consisting of aluminum. The other non-ferrous metals included in it are copper, stainless steel, zinc, lead, tin, and magnesium.

Where Does Zorba Scrap Come From?

Zorba Scrap comes in three different size particles, i.e. large, small, and fine. Each size needs to be treated differently.

Usually, the Zorba Scraps are found in three significant areas, packages, vehicles, and construction. Among these areas, vanished vehicles and aluminum beverage cans are the important areas where Zorba Scraps are found.

Collected Aluminum Scrap then ends up becoming new products such as food cans, soda cans, beverage cans, bicycles, motorcycles, food aluminum foils, window frames, airplane parts, etc.

Why Are Magnetic Separators Important?

Installing a combination of suitable magnetic separators is crucial in the recycling industry. For the best separation and sorting of metals, it is important to use the best magnetic equipment for recycling which helps create valuable marketable aluminum fractions. Moreover, optimal separation helps lower the ecological footprint and creates less waste to be disposed of.

All and all, the use of magnetic separators ensures the efficient separation of different metals, which is crucial for the recycling process. Jaykrishna Magnetics Pvt. Ltd is a leading magnetic separator manufacturer supplying a customizable range of magnetic separators for the recycling industry to suit specific requirements of diverse applications.

Magnetic Separator For Specific Applications

Magnetic Separator For Ferrous Impurities

For effective separation of ferrous metals larger than 1mm in size, specific magnetic separators are designed to continuously remove ferrous metal from product flow. Below are some of the best magnetic separators for removing ferrous impurities in the recycling industry.

- Overband Magnetic Separator

- Electromagnetic Overband Separator

- Magnetic Head Pulleys

- Drum Type Magnetic Separator

These magnetic separators help make the shredder flow metal free by accurately separating small iron particles.

Magnetic Separator For Non-Ferrous Material

The other material found in Zorba Scrap is non-ferrous metals which include mainly aluminum. Some of the best magnetic separators for removing non-ferrous impurities in the recycling industry are

- Eddy Current Separator

- Magnetic Plates

- Drum Type Magnetic Separator

Top Quality Magnetic Separators For Zorba Scrap Recycling Industry

Overband Magnetic Separator –

Overband Magnetic Separator is uniquely designed to separate ferrous particles from materials carried on a conveyor belt. Consisting of a permanent magnet suspended over the conveyor belt, the ferrous materials are attracted by the magnetic field of the moving conveyor belt.

Salient Features:

- Separator body covering

- Easy maintenance

- Strong construction

- High-Efficient Separation Process

- Long belt life

Drum Type Magnetic Separator –

Permanent Drum Type Magnetic Separator is widely used for separating magnetic materials from non-magnetic materials processed in large quantities. The separator consists of a rotating drum, which while rotating attracts the magnetic particles and the nonmagnetic material falls freely from the drum shell.

Salient Features:

- High-quality modern anisotropic permanent magnets

- Automatic Iron Separation for higher efficiency

- Enclosed design to prevent dusting and pollution

- Durable and rugged construction

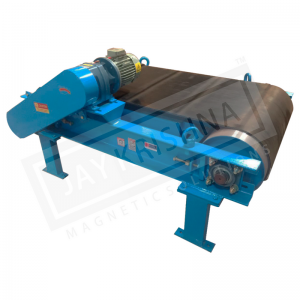

Eddy Current Separator –

Eddy Current Separator is one of the best and most preferred magnetic separators for separating and recovering non-ferrous metals from product flow. It uses a conveyor belt with high-speed magnetic rotor systems to separate metallic impurities from non-metallic impurities.

Salient Features:

- Tensile Equipment Structure

- No Loss Of Valuable Metals

- Requires Minimum Maintenance

- High-Quality Results

- Superior Protection Of Equipment In The Process

Permanent Magnetic Drum Pulley –

A magnetic head pulley is a widely used magnetic separator in the recycling industry to remove ferrous particles from materials transported on a conveyor belt. The magnetic roller of the separator extracts iron particles from the product stream and collects them under the conveyor belt.

Salient Features:

- Auto cleaning

- Magnetic field range from 2500 to 8500 gauss available

- Low maintenance

- Welded Construction

- Powerful anisotropic hard ferrite magnets and rare earth magnets

Finishing It Up

Selecting the correct magnetic separator is essential for the recycling industry and installing the right one can be beneficial for industrial productivity and better separation quality.

It might seem daunting, but we hope the above blog can help you find the right magnetic separator suitable for your application.

If you are looking for the greatest manufacturer of magnetic separators for the recycling industry – Jaykrishna Magnetics Pvt. Ltd. is the answer.

Being the industry leader for over a decade now, we have specialized in manufacturing the best quality magnetic separator to offer higher separation and lower maintenance in wide industries.

For product requirements for your Zorba separation line, email us today at info@jkmagnetic.com or contact us at: +91 9825326078, +91 93274 46310