What Are The Top Magnetic Separators Used For Beverage Cans Recycling

Today steel and aluminum are common materials used for packaging most Beverage cans. You must have also seen while buying food and drink products that the packaging of the product is either made from aluminum or steel.

These metals are majorly used due to their durability and lightweight construction. Luckily these materials can be recycled after their usage.

Aluminum and steel are infinitely recyclable without losing their quality as they can retain their properties throughout the recycling process.

But how can Beverage Cans be recycled? What is the importance of Beverage Cans recycling? Which magnetic separator is right for Beverage Cans recycling?

Well, that’s a lot of questions that can’t be left unanswered. Read ahead to know the answers to all these questions in detail.

Why Is It Important To Recycle Beverage Cans?

As said before, both steel and aluminum can be recycled infinite times without affecting quality. Beverage Cans are generally made of these metals, and recycling them offers numerous environmental benefits.

From conserving non-renewable fossil fuels to reducing energy consumption and gas emission into the atmosphere, recycling holds the utmost importance.

To elaborate, Aluminum is mined and extracted from bauxite, which has the compound alumina in it.

4 tons of bauxite contains 2 tons of alumina, which in the end yield only 1 ton of valuable aluminum that is used in buildings, transport, other industrial applications, and packaging.

Aluminum is one of the most cost-effective metals to recycle, and around 75% of all the aluminum ever made is still in circulation in the market.

Talking about steel, it is made of iron ore, limestone, and coal. Mining these materials has a huge environmental impact as these mining processes require large energy consumption, and the production process can also produce waste and emissions.

Hence, by recycling steel we can reduce energy consumption and wastage of raw materials.

Benefits Of Beverage Cans Recycling

- Saves Energy Consumption

- Prevents Environmental Degradation

- Reduction Of Landfills

- Profitable For Recyclers

- Satisfy The Increasing Demand

- Continuous Use Of Product

- Conserve Natural Resources

- Reduce Greenhouse Gas Emissions

Recycling Process Of Beverage Cans

- Step 1 – Beverage Cans Collection

- Step 2 – Sorting Of Metals

- Step 3 – Metal Shredding

- Step 4 – Magnetic Separation

- Step 5 – De-coating

- Step 6 – Melting Of Separated Materials

- Step 7 – Ingot Transportation

Different Types Of Magnetic Separators For Beverage Cans Recycling

If you are not recycling the Beverage Cans the right way, then you are risking contaminating an entire batch of recyclable materials. Choosing effective and most efficient Magnetic Separators for Beverage Cans Recycling is crucial to avoid any loss.

Here are some of the best Magnetic Separators used in Beverage Cans Recycling lines.

Eddy Current Separator

Eddy Current Separator is widely used in the recycling industry due to its optimum performance in recovering and removing non-ferrous metals from non-metallic materials.

From smallest to largest non-ferrous metals, the innovative design of the Eddy Current Separator enables advanced separation of non-ferrous metals like aluminum, copper, and other recycling products.

Salient Features

- Robust Construction With Anti-Vibration Pads

- Effective And Smooth Separation Process

- 2MT/hr to 15MT/hr Capacity

- Low Maintenance Design

- High Speed Magnetic Rotor System

Overband Magnetic Separator

Overband Magnetic Separator is another effective magnetic separator designed for the continuous removal of ferromagnetic particles in the recycling process.

The Overband Magnetic Separator manufactured by Jaykrishna Magnetics Pvt. Ltd. is renowned in the market for the effective separation of tramp ferrous material. We offer different types of Overband Magnetic Separators to suit diverse industry requirements.

Salient Features

- Automatic Removal Of Ferrous Contamination

- Long Belt Service Life

- Easy Maintenance

- Highly Efficient Separation

- Rugged Construction

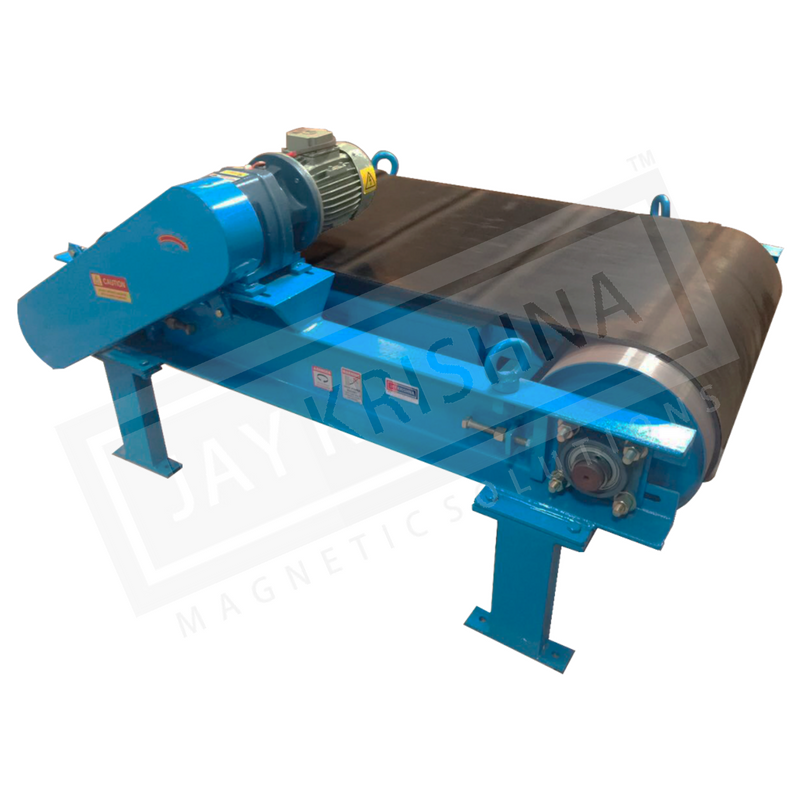

Magnetic Drum Pulley

Magnetic Drum Pulley is specially designed for conveyor systems for trouble-free separation and protection against tramp iron contamination.

Recycling industries use Magnetic Drum Pulleys to segregate steel and other ferrous contaminations like cans.

Salient Features

- Easy To Install

- Requires Minimal Maintenance

- Greater Magnetic Strength

- Bored And Keyed Hubs

Magnetic Plate

Last but not least, Magnetic Plate is also used for the Beverage Cans recycling process. It is used to remove tramp iron such as bolts, nuts, plastics, and other contamination from materials and provides protection against any occasional damage caused by iron bits.

Jaykrishna Magnetics Pvt. Ltd. specially designs Magnetic Plates for recycling industries with the ability to capture tramp metal in gravity free-fall applications.

Salient Features

- Easy To Install

- No Maintenance

- Stainless Steel Construction

- Manual Cleaning Option

- High Coercivity Modern Anisotropic

Lastly

Indeed there are plenty of magnetic separators for the recycling industry. Ultimately, it depends on various factors to decide which one is ideal for your application.

However, above were the different types of magnetic separators widely used in Beverage Cans recycling for the removal and recovery of materials.

If you need further help with selecting the best magnetic separator for your recycling needs, don’t hesitate to contact us.

Jaykrishna Magnetics Pvt. Ltd. is a leading Magnetic Separator manufacturer in India. We supply a diverse range of Magnetic Separators suitable for recycling and metal separation plants.

So if you are looking for the top quality magnetic separator in the market, then request your FREE quote with us today.

Read More:

- Magnetic Separation Technology For Waste Recycling Industry

- Magnetic Separation Equipment For PET Plastic Recycling

- High-Quality Magnetic Separators For Auto-Shredder Residue Recycling