Types of Vibrating Screens: A Complete Detailed Guide

Introduction

Vibrating Screen is widely used for the industrial screening process. It segregates various types of mixtures, such as powder, rocks, and other fine materials.

Recycling, waste management, and many other industries prefer vibrating screens for material handling.

However, when it comes to choosing a type of vibrating screen, industries do give a lot of thought to understanding and determining the right type for their application.

It makes perfect sense: Every vibrating screen type has different processing capabilities, screening efficiency, and vibration intensity. Selecting the right type of vibrating screen is essential for better outcomes and the screening process.

Let’s explore 10 common types of vibrating screens, their features, advantages, applications, and a lot more.

Keep scrolling to learn everything.

What Is A Vibrating Screen?

Vibrating Screens are one of the most popular choices for major industrial applications. It is designed to work through vibration generated by the vibratory motor.

The upper vibratory rotator in the vibrating screen generates plane gyration vibration, whereas the lower rotator produces cone-shaped vibration. Together, this vibratory effect causes the screen to create a rotating vibration to separate the materials.

The vibrating screen has high vibration intensity, large vibration amplitude, and low frequency that help streamline the screening process of bulk materials. It separates bulk materials based on their size, shape, and density.

How Does A Vibrating Screen Work?

As their name suggests, vibrating screens separate and sort bulk materials by their size, shape, and density using vibrations.

Vibrating makes this happen by breaking down the bulk material particles through vibration and forcing them to separate into fine crumbles.

Fine particles fall through the pierced screen surface, whereas the oversized particles are transported across the screen.

Features Of Vibrating Screen

Optimum Design:

Has a robust and lightweight design with special specifications such as dust-tight and explosion-proof.

Isolating Structure:

Available in enclosed design for safe and dust-proof operation in industries where hygiene is important.

Wide Variation:

Available in various types and technologies, such as electromagnetics screens and ultrasonic screens, for the best screening process.

Compatible & Adaptable:

Easily compatible with various types of decks and systems, as well as can adapt your choice of workflow.

Stable Performance:

It has dynamic response stability, which ensures stable, reliable, and structural screening performance.

Accurate Screening:

The machine has high screening precision and capacity, allowing accurate screening at the ideal material and flow rate.

Adjustable Flow Rate:

The screening capacity and vibration speed can be adjusted to control the material flow rate.

Low Power Consumption:

The screening process takes place through the vibration generated by the motor, which requires less power to operate.

Non-Clogging:

Through high-speed vibration and efficient screen cloth, there is very little chance of material clogging during the process.

Flexible Installation:

It has a vibration-proof design with very little vibration transfer to the floor. This makes it easy to install as per the application requirement.

Easy Maintenance:

It has a simple structure with easy-to-dismantle and changing components. Moreover, the structure does not have wearing components, requires no lubrication, and offers a long service life with maintenance-free vibrating elements.

Large Volume Processing:

It has a high material processing capacity, allowing large-volume processing possible with material clogging.

Types Of Vibrating Screen

1. Linear Vibrating Screen

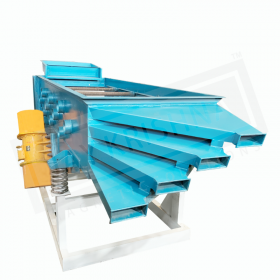

A linear vibrating screen is a robust screening machine excited to a linear vibration. It works on reverse motors to move particles forward on the screen surface.

It is ideal for both light and heavy-duty applications and can handle high-rate multiple fractions separation.

Features:

- Stable and reliable

- Low consumption

- Low noise

- Long service life

- Stable vibration shape

- High screening efficiency

2. Circular Vibrating Screen

A circular vibrating screen works on the principle of gyratory motion generated by a vibratory motor. The vibrating screen motion generated runs both vertically and horizontally and can be easily adjusted as per the screening requirements.

It is used to classify medium to bulk materials with large specific gravity, large particles, and high hardness. Other than material classification, the screening machine is also used to accurately remove oversized pollutants.

Features:

- High screening efficiency

- Easy maintenance

- High capacity

- Easy installation

- Maximum flexibility

3. Elliptical Vibrating Screen

The elliptical vibrating screen has an elliptical motion track and integrates the benefits of both linear and circular vibrating screens.

This type of vibrating screen is highly efficient for mines, quarries, sand plants, and other screening applications. The elliptical vibrating screen has a large material processing capacity, which provides bulk material handling and separation ability.

Features:

- Good permeability

- Large processing capacity

- Small installation height

- High screening accuracy

4. Roller Screen

Roller screens is an efficient screening equipment designed for scalping and removal of fine materials from the feed before primary crushing.

It consists of a series of several single-screen rollers that are horizontally arranged on the screening machine. These screen rollers are also known as eccentric discs.

As the material passes through the roller screen, the fine material free falls through the discs, and bulk material is carried by the rollers and discharged from the outlets.

Features:

- High screening efficiency

- Accurate processing

- Low maintenance

- Self-cleaning

5. Rotary Vibrating Screen

The rotary vibrating screen is one of the most sought-after screening machines for material classification. It can be used for impurity separation, material classification, and filtration processes in various industries such as food, chemical, metal, mining, and others.

Its unique features ensure no blocking of mesh, no material storage in the screening machine, no leakage and flying powder, and only a better screening process and quality output.

Features:

- Fully enclosed structure

- High precision

- Enhanced efficiency

- Low noise

6. Inclined Screen

Inclined screens are generally mounted at an inclination angle of 15° to 30°. Powered by an electric motor, the material flow is created by gravity acceleration created on the screen. Moreover, this screening machine allows material classification in multiple grades.

Features:

- Versatile

- Robust

- High capacity

- Adjustable inclination

7. Horizontal Screen

Horizontal screens are great for handling sticky materials. Installed at a slight inclination angle, it is ideal for various industrial applications such as quarries, mines, and mobile screening operations.

Features:

- Exceptional screen permeability

- High processing capacity

- Low installation height

- Maximum operational flexibility

Advantages Of Using A Vibrating Screen

1. Lower Operational Costs

Vibrating screens are renowned for their simple, durable, and sturdy structure. The unique structure of vibrating screens makes them less expensive than complicated vibrating screeners.

Not only this, but the operational cost of vibrating screens is low as it consumes much less power and energy, resulting in reduced operating costs.

2. Less Maintenance And Downtime

Unlike other industrial equipment, vibrating screens require less maintenance due to fewer failures and components wear and tear.

Vibrating screens are designed to operate through the vibration force; hence, there are very less movements of other machine parts. This, as a result, reduces both downtime and overall maintenance costs.

3. Improved Material Processing

Vibrating screens are the best choice for the industrial screening process. It seamlessly separates oversized particles from fine materials with high efficiency for better quality material output.

4. Enhanced Efficiency

Vibrating screens are well suited to meet various screening requirements with full efficiency. It effortlessly controls the flow of higher feed and maintains efficient screening functions at a consistent flow rate.

5. Better Screening Performance

Vibrating screens perform most efficiently with a higher flow rate without blinding of the screen or material backflow. It consistently manages the feed flow rate, resulting in better screening performance.

Vibrating Screen Applications

Vibrating screens are used in a wide range of industries, such as:

- Food Industry

- Oil Industry

- Agro Products Manufacturing Industry

- Pharmaceuticals

- Chemical Industry

- Mineral Processing Plants

- Mining

- Rubber Industry

- Paper Industry

- Sugar Industry

To Conclude

Now that we’ve reviewed different types of vibrating screens, you hopefully have a better idea of which one is right for your application.

Well, there’s one more thing you should choose right – The right vibrating screen manufacturer.

Material classification, filtration, and handling require a quality range of vibrating screens; hence, it is essential to choose a manufacturer with proven expertise in manufacturing the best quality vibrating screens.

Jaykrishna Magnetics Pvt. Ltd. is a leading manufacturer of vibrating screens in India. Using advanced technology and industrial expertise, we design an excellent vibrating screen that meets customers’ requirements for more efficient, more precise screening.

Interested in setting up your material handling system?

Contact us today

Read more:-

Top Magnetic Separators & Vibratory Equipment For Municipal Solid Waste Recycling (MSW)

Top 6 Magnetic Separators For Incineration Bottom Ash Recycling