Top 4 Magnetic Separator For Recycling Line

In today’s times, recycling of products is extremely popular. Recycling is a million dollar industry as it offers tremendous economic opportunities and imparts positive environmental impact and it is applicable to the metal industry. Jaykrishna Magnetics Pvt. Ltd is playing a major role in the field of magnetic separator manufacturing from last many years. We have newly developed an extensive range of magnetic separators for the recycling lines to separate non-ferrous impurities from product stream.

Top 4 Magnetic Separator for recycling Line:

- Eddy Current Separator

- Overband Magnetic Separator

- Permanent Magnetic Separator

- Suspension Magnet

#1. Eddy Current Separator:

Our highly efficient Eddy current separator is the most advanced magnetic separator which are commonly used to separate non-ferrous metals for missed waste and other streams. It purely separate aluminium, copper, bras and other non-ferrous metals from any product stream municipal solids waste recycling, scarp residue, auto shredding, aluminium recycling, pet recycling and other recyclable.

Eddy Current separator are very popular and innovative machine with two vibratory feeder developed by Jaykrishna Magnetics Pvt. Ltd. for effective separation process.

Features:

- Solid structured with anti-vibration pads

- No loss valuable materials

- Low maintenance

- Protected other recycling equipment

- High yields of non-ferrous metals recovery

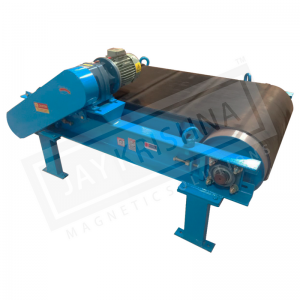

#2. Overband Magnetic Separator:

Jaykrishna Magnetics Pvt. Ltd. has developed permanent magnetic overband separator that are designed to eliminate metal from the product stream. We manufacture overband magnetic separators of two types overband and inline. It can be available as per the customers’ requirement.

Overband mainly used for the metal separation in recycling plants like rubber, aluminium, pet, and many more recyclables.

Features

- Used in either ceramic or powerful rare magnet

- Separator body covering

- Low maintenance

- Roughest construction

- High efficiency

- Long belt life

#3. Permanent Magnet Drum Pulley

Permanent magnet drum pulley replaces the drive pulley at the end of conveyor belts. We have developed magnetic drum pulley for various industrial applications like minerals, chemicals, food processing, recycling, plastic, cement, etc. Basically, it separates the metal contamination from the product stream.

Features:

- Self cleaning option available as per the requirement

- The magnetic field range 2500 to 8500 gauss is available

- No maintenance

- All welded body face construction

- Pulley either use ceramic magnet or powerful rare earth magnet

#4. Suspension Magnet

Jaykrishna Magnetics Pvt. Ltd. suspension type magnets are mainly useful for carrying metal product. It also extract the metal impurities which passed on the conveyor belt and vibratory feeder in the processing lines.

We have designed two types of suspension magnets, 1. Suspension magnet and 2. Electromagnetic suspension magnets. Our suspension magnet can be mounted on various structures.

Features:

- Rough construction

- No external power required

- Quickly installed in existing plants

- Maintenance free

Jaykrishna Magnetics Pvt. Ltd. is a world’s well-known magnetic separator and vibratory feeder manufacturing company located in India. Our highly-skilled team is the reason for our long product range and innovative designs. For a complete list of magnetic separator for recycling, lines visit our website: www.jkmagnetic.com

For any further inquiry email us on info@jkmagnetic.com our sales representatives will contact you back for further assistance.