Permanent Magnetic Separator For Europe Recycling

As we all know magnetics separators are the most useful processing equipment for recycling industries. Almost every recycling industry requires magnetic separators for the metal separation from the product stream.

Europe recycling market is the most emerging market of the current time. Latest trends show the growth of every recycling industry has increased substantially. Policies of Europe waste management is made with the aim to reduce the environmental and health impacts of waste to improve the resource efficiency.

Countries in Europe are going to recycle at least 50% of their municipal waste by 2020. Recycling benefits both the environment and economy. Recycling can benefit for safe and reliable products that are present in every corner of our daily life. Recycled non-ferrous metals can also be found in many essential products such as an aeroplane, cars, aluminum cans, cables, etc. While recycling such metals magnetics separators plays a very vital role in it.

Jaykrishna Magnetics Pvt. Ltd. has developed the most efficient magnetic separators specially for the recycling industries in Europe as per the latest industrial standard. Below is the list of magnetic separators which are used in the recycling industry.

1. Overband Magnetic Separators:

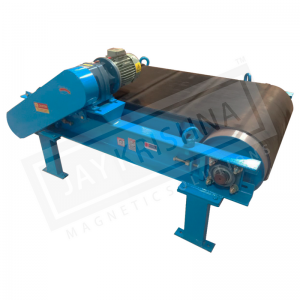

Overband magnetic separators by Jaykrishna Magnetics Pvt. Ltd. are the highly-effective magnetic separator for the continuous removal of tramp ferrous material from the product line. Overband magnetic separators are also called OBMS in the market.

We’ve designed two types of overband magnetic separators:

Our machine can handle the weight up to 20kg. Most suitable magnetic separators with operating height up to 450mm. It can be used in vibratory conveyor, aluminum scrap recycling, auto shredding, rubber recycling, plastic scrap recycling, etc.

Check Video:

2. Eddy Current Separator:

Jaykrishna Magnetics Pvt. Ltd. has designed the most innovative magnetic separator called Eddy Current Separator for the recycling industry. We’ve used a magnetic field to separate non-ferrous metals from waste after all ferrous metals have been removed previously by some arrangement of magnets. Eddy current separators make use of eddy currents to effectively separate the non-ferrous metals. Eddy current separators designed by Jaykrishna Magnetics Pvt. Ltd. can be used in aluminum scrap recycling, rubber scrap recycling, e-waste recycling municipal solid waste, pet flakes recycling, plastic scrap recycling, etc.

Eddy current separators designed by Jaykrishna Magnetics Pvt. Ltd. can be used in aluminum scrap recycling, rubber scrap recycling, e-waste recycling municipal solid waste, pet flakes recycling, plastic scrap recycling, etc.

One of the most recent and exciting innovations in material separation market is the non-ferrous eddy current separator.

Check Video:

3. Magnetic Drum:

Magnetic drum by Jaykrishna Magnetics Pvt. Ltd. is designed for the continuous separation process. It is the most effective for high-flow and heavy contamination applications. Our magnetic drum is the most effective magnetic separator for removing ferrous particles from many non-ferrous powder and granules. Our magnetic drum can be used in auto shredding, rubber recycling, aluminum scrap recycling, plastic scrap recycling, pet flakes recycling and many more.

Our magnetic drum can be used in auto shredding, rubber recycling, aluminum scrap recycling, plastic scrap recycling, pet flakes recycling and many more.

Check Video:

The Best Part.

Magnetic separators designed by Jaykrishna Magnetics Pvt. Ltd. are the most effective magnetic separators for recycling industry in Europe. We’ve used high-strength magnets in our machine for separation the material effectively. Our experienced team has designed this machine for getting the desired separation results.

Here’s the deal.

Jaykrishna Magnetics Pvt. Ltd. has manufactured a wide range of magnetic separators for various recycling industries. Our product range includes many other types of separation technology for recycling purpose. To know more about our magnetic separators, visit our website: www.jkmagnetic.com

For further inquiry and other machinery, details email us on info@jkmagnetic.com

We are developing the most advanced magnetic separators and vibratory equipments for recycling industries from last 38 years.