Magnetic Separation Technology For A Recycling Industry

“Magnetic Separation Technology is the most important technology for any recycling industry.”

Magnetic Separation is the process, in which the “magnetically caused material is detached easily” by using a magnetic force. From last many years, magnetic separators are used for various separation process in recycling industry like Glass recycling, Scrap material, Pet flakes, Plastic recycling, Rubber recycling, Municipal solid waste (MSW), e-waste recycling etc.

Magnetic separation technology is one of the best methods for sorting recyclable materials. It uses the power of magnetic devices to sort ferrous products from non-magnetic debris.

Importance of magnetic separator

Magnetic Separator is the most trusted machine used to recover metal from the waste materials. It is known for the easy separation process to detach fine particles which have poor magnetic properties. Magnetic separator provides the excellent separating effect, as it uses dynamic magnetic system design. Recycling industries are using magnetic separator because of its various advantages like large handling capacity, low maintenance rate, simple structure and adjustable magnetic field intensity.

It easily removes or sorts ferrous-responsive materials from those that are non-magnetic. Or it includes the process of materials sorting and separation.

Magnetic Separators for Recycling Industry

Eddy Current Separator, Overband magnetic separator, and Magnetic Pulley are the most widely used Magnetic separator that is used in recycling industry to detach metal pieces from the products.

Common separated metals include:

- Overband / Suspension magnet or magnetic pulley are used to separate various ferromagnetic particles like iron, steel, and work hardened stainless steel (SS).

- Eddy Current separator is used to detach non-ferromagnetic particles like aluminium and copper.

Eddy Current Separator

Eddy Current Separator is the most trusted separator, used to segregate valuable non-ferrous metals like aluminium, brass, copper, lead etc. It has an advantage of high frequency and high separation capability. Eddy Current Separator is robustly constructed with anti-vibration pads and its powerful quality of magnets provides the best and smooth separation for the recycling industry.

It has a capacity from 2MT/hr to 15MT/hr. Eddy Current provides its best separation service in various fields of recycling industry like plastic, rubber, glass, municipal solid waste, e-waste, pet etc. And the industries can take a huge advantage of using eddy current separator for their current application.

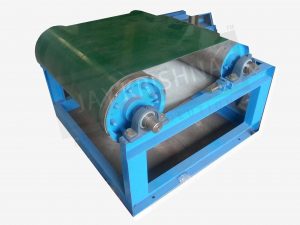

Overband Magnetic Separator

Overband Magnetic Separator is known for providing the excellent service of separating tramp iron from the material that is being processed on the conveyor belt or a vibratory feeder. Overband magnetic separator is used to protect machines like crushers, shredders by removing ferrous particles and it easily removes the heavy dust particles. It is used in many industries like food, sponge iron, charcoal, glass etc.

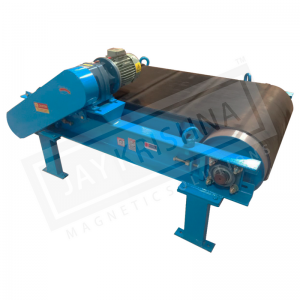

Magnetic Head Pulleys

Specially designed Magnetic Head Pulley to detach tramp metals like steel, bucket teeth, bore crowns, bar scrap, chains, and tools. Recycling industries are using Magnetic Head Pulleys to segregate steel, municipal waste and many other ferrous contaminations like cans, nuts, nails etc.

And it can be easily installed at conveyor discharge and mostly used in paper, wood, steel, mining recycling, scrap yard, municipal recycling and many other recycling plants.

But there’s a catch

From last many decades, Manufacturing industries are playing a most crucial role in our global economy. They are trying to develop high capacity and high-frequency pumps for the recycling industry, because they’re facing an issue of sorting recyclable material by removing various tramp metals like steel, bucket teeth, bore crowns etc.

Machines are not able to provide the best separation solution in the various field of recycling industry like plastic, rubber, glass, municipal solid waste, e-waste, pet etc. After facing these all issues regularly they are looking for high capacity which is having high-intensity magnets to remove impurities easily.

Here’s the deal

Jaykrishna magnetic Pvt. Ltd. understands all problems that the “industries” are facing now!!! We design a machine which is of high capacity that easily recovers metal from the waste materials. Our machines are evolved by using the latest technology that can be easily operated and to provide best separation results in various fields of the recycling industry.

The Best part

We are famous for manufacturing and supplying magnetic separators which is of high capacity that easily provides the perfect separation solution. Jaykrishna Magnetic Pvt. Ltd. has 38+ years of experience in developing machines which are highly efficient and easy to handle.

Our magnetic separators are designed by the team of experts who have a great knowledge of designing and developing various types of magnetic separators and vibratory equipment. Our experts take care of client’s need, before supplying any machine to them.

Our machines are installed in various fields of recycling industry like plastic, rubber, glass, municipal solid waste, e-waste, pet etc. We also design different types of magnetic separators like Eddy current separators, Overband Magnetic Separator and Magnetic Head Pulley as per the client’s requirement to deliver them a “best product”.

If you are facing a problem of extracting tramp metals steel, bucket teeth, bore crowns etc. then feel free to contact us. Our team will get back to you with the best and effective solution that solves your problem.

For more information about our magnetic separators visit our website: www.jkmagnetic.com