Magnets, Electromagnetic & Eddy Current Separator For Recycling Industries

Recycling is, in present times the need of the hour. Through recycling, used materials are converted into products that can be used again. E.g., scrap metals are repurposed into cans, paper waste is recycled and then remade into disposable paper products, etc. This not only helps the environment as it helps to conserve our planet’s natural resources, it can also prove to be a cost-effective option.

For recycling to be done, the recycling industry has been setup, where machines are used to recycle different waste products. This industry carries out plastic recycling, aluminum recycling, other metals recycling, paper recycling, and many more types of recycling. Each of these need a different method of recycling, for which there exists a different machine. But, even before that, the waste materials need to be processed to obtain the proper pure waste streams.

Out of the mixed waste streams, the material that we want to recycle needs to be filtered out, and this can be done effectively through magnetic, vibratory, and eddy current separation. Such separation processes play an important role in the recycling process.

This why their need and importance have increased, which has also led to an increase in their usage. At Jaykrishna Magnetics Pvt. Ltd. we produce and manufacture all of these types of machines and equipment products that cater to the recycling industry. They include magnetic, electromagnetic, and eddy current separators. Here is a brief overview of them:

Magnets

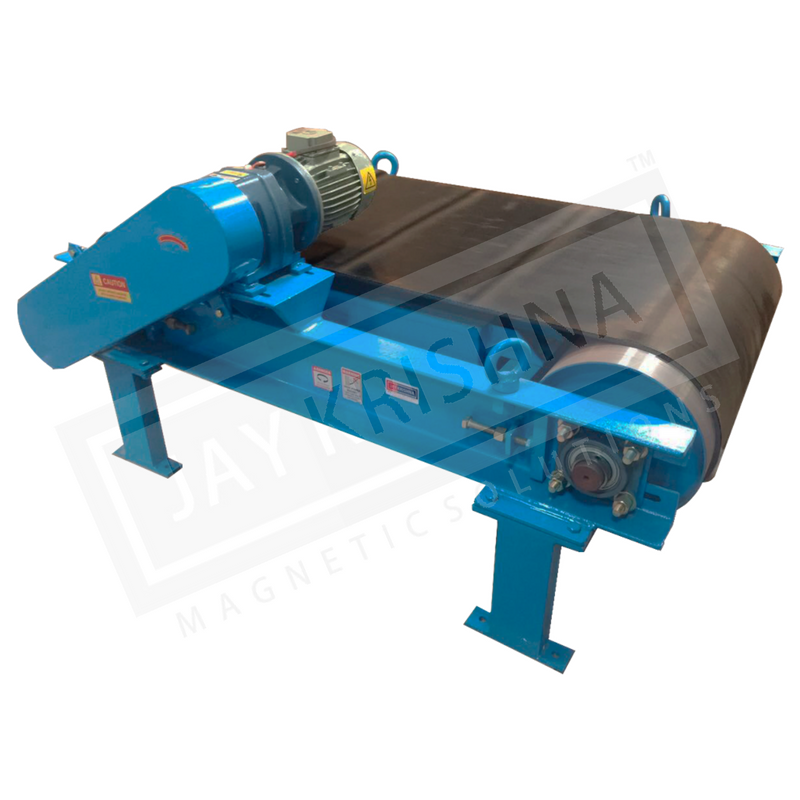

1-Overband Magnetic Separator:

This type of magnetic separator is an effective means of separating huge amounts of ferrous metals. An Overband Separator is fitted above conveyor belts that contain the materials and the separator continuously eliminates impurities from the material flow. The benefit of using this type of equipment is that it has a low cost of maintenance, it is easy to install.

2-Suspension Magnet:

This type of magnets is similar to an Overband Separator in the sense that it is also suspended above a conveyor belt but a Suspension Magnet is able to filter and separate material flows with low contamination. If the frequency of impurities is higher in the material flow, the magnet will be needed to be cleaned frequently. Both of these magnets can be used according to the amount of contamination.

Both of these magnets can be used according to the amount of contamination.

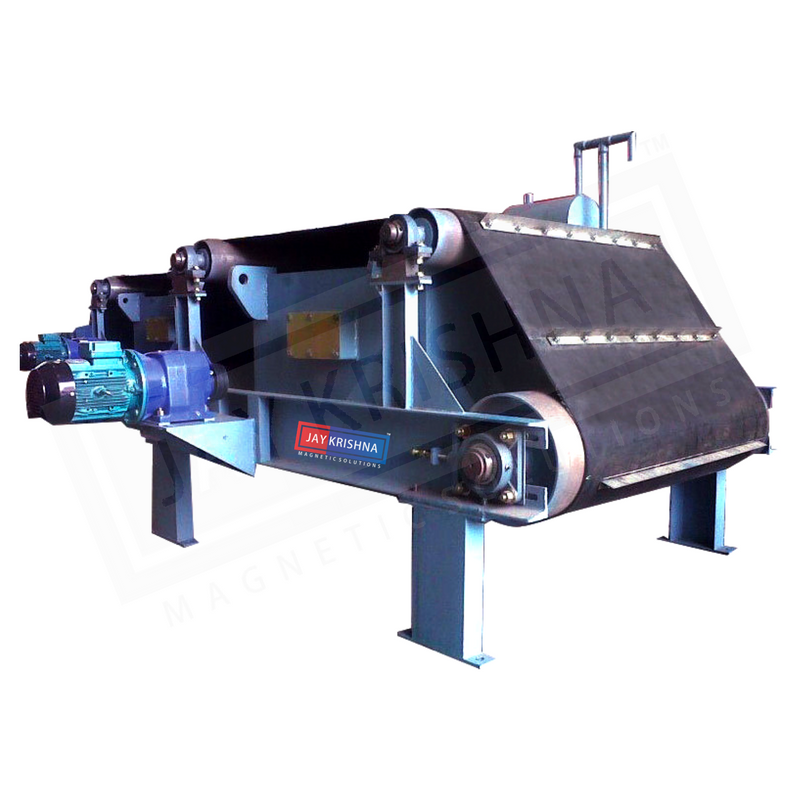

Electromagnetic Overband Magnetic Separator

Electromagnetic Overband Magnetic Separator is used when automatic removal of impurities and tramp metals is required. This type of separator offers continuous automatic cleaning. With Electro magnets, the magnetic field and intensity are more efficient, that too with low power consumption.

Eddy Current Separator

Eddy Current Separators are used to separate non-ferrous metals from waste and material streams. It is a recent and exciting innovation for non-ferrous metal separation. This separator can separate aluminum, copper, brass, and other non-ferrous metals quite efficiently.

Within the separator, a rotor consisting of magnet blocks [depending on an application] spins at a high speed to produce an ‘eddy current’. This eddy current reacts with different metals, according to their specific mass and resistivity to create a repelling force that leads to separation.

Within the separator, a rotor consisting of magnet blocks [depending on an application] spins at a high speed to produce an ‘eddy current’. This eddy current reacts with different metals, according to their specific mass and resistivity to create a repelling force that leads to separation.

Magnetic separation plays an important part in the recycling process and contributes to the overall process that helps our planet. At Jaykrishna Magnetics Pvt. Ltd. we build, manufacture, and produce equipment that are strong, durable, and efficient. We cater to many types of industries and never fail to deliver high-quality results.