5 Magnetic Separators Used in Pet Food Processing

Like any human being, the pets are supposed to be fed the high-quality food. Their nutrition and health are equally important and vital as that of any mankind. For us, there are all sorts of technological advancement, be it industries, factories or any other. However, the need to introduce robust machines for processing the pet food is very much required. Not only will it enable all the pets to better nutrition, but stretch their longevity by a couple of years. It all depends upon the kind of food that goes into your pet. For the sole purpose of providing a healthy and nutritious diet to the pet, the specialised machinery has been installed. Various series of magnetic separators are instilled for a thorough refining of the food.

These machines remove the stubborn toxins which hinder any pet’s growth and have an adverse impact over their organs. Thus, the vital machines are necessary in order to deliver a clean, enriched and healthy pet food. Apart from this, the metal contaminants must be removed before the final product goes out for sell. The pet food processing is undertaken mainly by magnetic separators and magnetic detectors. Ensuring no toxic or non-ferrous metal or metallic impurities is left out in the food components.

Here’s a list of magnetic separators which play a crucial role in bearing 100% contaminant-free final pet food.

1. Plate Magnet

As the name suggests, Plate Magnet is mainly utilised for removing the tramp iron from the material flow. For the convenience, it is designed and made available in various shapes and sizes. In order to meet the different industrial requirement, these magnets are applied in the specific operations and plants. Ideally, the plate magnet is used for eradicating the impurities like bolts, nuts, wire bits, nails and more. All the impurities are removed from the mobile material flow so that the result is completely contaminant-free and pure.

2. Pneumatically Operated Magnetic Trap

Specially designed for the corrosive chemicals, the Magnetic Trap is operated pneumatically. Mainly to filter out the harmful metal contaminants from the highly viscous materials. The performance of the pneumatically operated magnetic trap is enhanced to reach the superior level and increase the reliability. It functions to segregate the harmful chemicals using a magnetic gradient from the material. Enables a clean and pure pet food material at the final outlet.

3. Drawer Magnet

This machine is structured to refine the magnetic impurities from the pipeline. Drawer Magnet is fitted on one opening of the existing pipeline or the outlet. The machine consists of two permanent magnetic grids mounted over one another. Mainly utilised in the pulverisers, classifier and blenders for procuring a clean flow of material from the pipeline. Talking about the grids, they are easily replaceable and cleaned manually. The permanent magnets are basically the rods containing hard-ferritic ceramic magnets / rare earth magnets for an easy separation of impurities. Thus, allowing the material to pass through without any contaminants or metallic impurities.

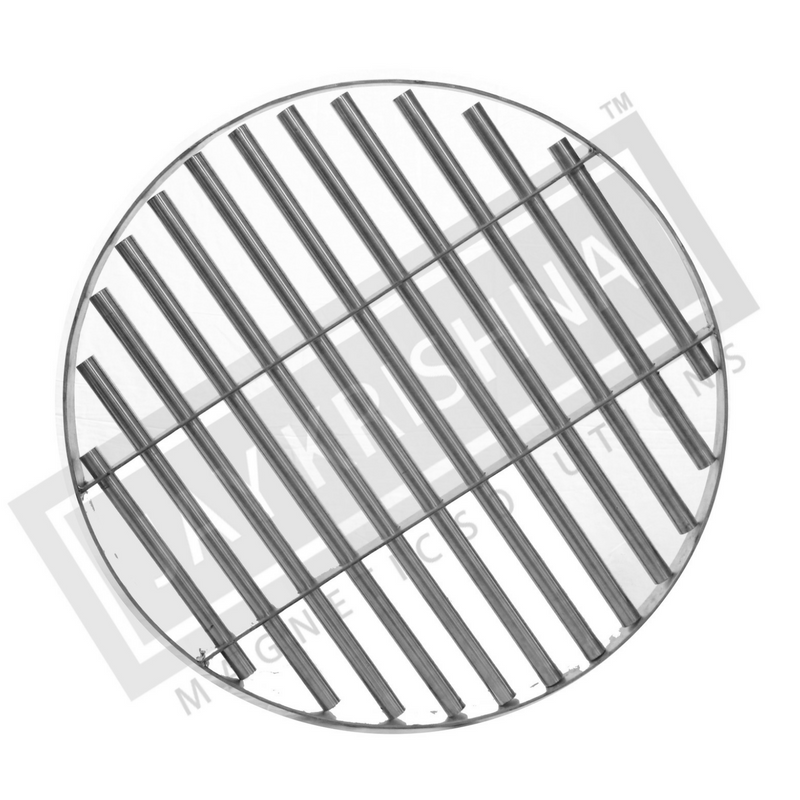

4. Magnetic Grill

An effective machine made out of robust material like stainless steel. This provides a high-gradient and high-intensity magnetic field in order to eradicate the ferrous impurities from the materials. The material flowing on the conveyor belt is free-flowing which allows the magnetic intensity to separate the ferrous contaminants. Magnetic Grill is installed at the opening of floor for protecting the crucial equipment and ensure the purity of product is not compromised. Thus, laying an elevated protection to the final product.

5. Hump Magnet

The perfect magnetic separator for the vertical flow of material. The Magnetic Humps are used for segregating the fine metals from the pet food like powder, granules and other forms. On top of this, it consists of multiple plate magnets in the vertical spouts. As and when the material is fed into the hump magnet, it hits the first magnet where the impurities are stuck. Further, it is thoroughly cleansed and refined after hitting the second magnet, making sure a smooth flow of material. Along with this, the magnets can be easily opened for collecting the impurities and cleaning it up. Making it a suitable machinery for the magnetic separation process of pet food.

Lastly

Jaykrishna Magnetics Pvt. Ltd. has been the prime manufacturer and supplier of robust magnetic separators and vibratory feeders. From constructing the machineries to partnering with the abroad clients, we are motivated to delivering more than just good. To bind a link among the domestic clients and serving their deliverables before time has been the paramount actionable motto. Moreover, it is our professional and expert union of skilled engineers who put in real efforts in assembling the huge range of magnetic separators for different industrial requirement.