Vibrating Screening Machine – For Rubber Recycling Plants

Do You Know?

Nowadays, merely 23 million tons of natural rubber gets produced and processed worldwide!

Even from the 1830s tenure, the worldwide consumption of natural rubber was 150 tons which gradually increased by spans and got denoted as an essential raw material in more than 40,000 day-to-day products such as car tires, toys, surgical gloves, and even in aircraft.

After getting operated on these massive numbers of products, rubbers’ recycling process has become a necessity as it saves chemical energy from surroundings and also reduces greenhouse gasses.

But according to global statistics ratio of only 3–15% of rubbers get recycled, which isn’t a great number but at least an effort that can’t be left insignificant.

The whole process of rubber recycling is particularly done in their specific rubber recycling plants, where they process used or irreparable rubbers into a new rubber product and offer environmental benefits too.

When rubber enters the recycling process, its major point to consider is impurities removal as impured rubber won’t be able to deliver quality or work as one’s requirement and would be considered “no-meaning” of the entire rubber recycling process.

And to help industries with the same, first some of the hand processes were considered in use – which was labeled as “too-time-consuming” processes. Secondly, heating processes were operated by rubber recycling industries that led to a “decrease in the rubber quality”.

In both cases, rubber industries should face huge losses – lately for which Vibrating Screening Machines helped to overcome each of them with perks of precision and accuracy.

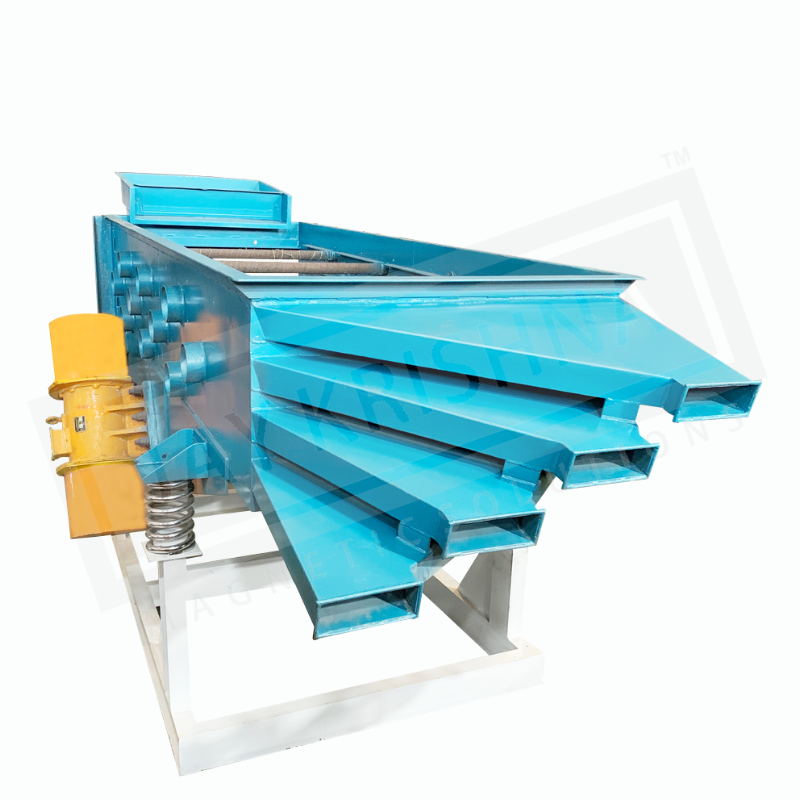

What Is a Vibrating Screening Machine?

Vibrating Screening Machines are designed for the removal of minute contamination to oversized impurities such as minerals, powders, ceramics, and more from components.

In recycling industries, not only undersized but oversized impurities bugs too as if its removal isn’t done properly, then it can be harmful to machinery and the entire recycling process too.

While Vibrating Screening Machine breaks down those big contaminants into small pieces and drives smoothly to the discharge point – assuring the machine’s and the industry’s safeness with accuracy.

How Vibrating Screening Machine Helps in the Rubber Recycling Industry?

As the recycling components increase, the proportion of contamination increases too that includes rubber powders, metallic contaminations, and impure minerals which can get unrecognized by humans.

Vibrating Screening Machine helps recycle industries to overcome the same without getting overlooked by someone and less electric consumption. Vibrating Screening Machine is bifurcated into three subtypes that include Single Deck Vibrating Screens, Double Deck Vibrating Screens, and Multi-Deck Vibrating Screens

Each of them consists of different yet exceptional systems:

1. Single Deck Vibrating Screens: It is simple in structure and maintenance that helps in screening contamination like powders from Spices, Plastic, Packaging Line, and many other industrial segments whose requirements include accuracy but is lower in the portion of the element.

2. Double Deck Vibrating Screens: It is mainly operated at power plants, construction industries, and steel plants where contaminants are most based on metallic elements. Double Deck Vibrating Screens are ideal for their high-frequency handling and impurities separation from fine elements which are less than 5mm.

3. Multi-Deck Vibrating Screens: These are the most superior and faster-vibrating screens that can precisely separate minerals, ceramics, refractories, and other impure powders. Multi-Deck Vibrating Screens are available in different sizes and can also be specifically manufactured, it offers a wide range of element adaptability with multiple ending points which makes processes way more accurate and precise.

Working Principle of Vibrating Screening Machine

The Vibrating Screening Machine is an impurity separation machine that basically conducts the whole process on the basis of vibration in order to screen impurities such as chemicals, powders, and other contaminants classified by their sizes.

The process starts with the addition of contaminated components to the Vibrating Screening Machine’s opener, which gets driven down to vibratory frames – that further move fine materials and impurities to different decks and lastly get collected by different containers.

Vibrating Screening Machines also consist of air-mount isolators that enable machinery to pull out the heat produced during the process that lower the burst and machinery heating issues to 0% and assure long work life and crystal-clear separation.

Salient Features of Vibrating Screening Machine

- Accurate Processing

- Low Maintenance

- Higher Screening Efficiency

- Removal of all contaminations

- Improving Material Quality

- Less Time Consuming

- Long Workability

Vibrating Screening Machine Applications

- Rubber Industry

- Food Industry

- Agro Products

- Oil Industry

- Chemical Industry

- Pharmaceuticals

- Metal Powder

- Bulk Foods

- Refractory

- Mineral Processing Plants

- Plastic Industry

- Sugar Manufacturing

Takeaways:

Here are quick informative recollections, we covered throughout the blog – the importance of rubber and its recycling processes, the number of ratios we covered in rubber recycling, and how and why impurities can harm rubber throughout the recycling processes.

Then the icon in the story “Vibrating Screening Machine” – operated in multiple industries for accurate yet precise contamination separation with the provision of high work efficiency and low maintenance, its uses, working principle, and applications. If you still have some queries, you may drop them in the comment box below.

Last but not least – We, Jaykrishna Magnetics Pvt Ltd. are a team of highly-skilled engineers, mastered in the market for 40+ years. Our top-notch separators and their efficiency have been marked throughout the span. Our product list includes Vibrating Screening Machines, Magnetic Separators, Electromagnetic equipment, Mineral processing equipment, and many others that assist tons of industries that cater not only to domestic but international markets too, which named us as one of the most accredited names in the separation tech industry.