Magnetic Separators for Sorting Recyclable Materials

The recovery of metals from waste or the raw material is becoming more and more crucial because raw materials are becoming more limited and the worth of waste disposal continues to arise.

As an outcome, the demand for recycled metals got increased. So many industries have manufactured various separators that can separate pieces of metal from the waste. These are often very useful metals, which often makes the payback time very short. Also, these waste products can be reusable for new applications.

But there is a problem!!

Magnetic separator manufactured by different industries is not so efficient in the separation process. So, it’s a very big problem for many recycling industries. After giving a huge amount for the magnetic separator they are not able to get a desirable result.

So, what recycling industries can do?

There is only one solution for the recycling industries they need to purchase magnetic separator from the industry who has years of experience to manufactured highly advanced magnetic separator.

Where they can find advance magnetic separator?

Jaykrishna Magnetics Pvt. Ltd. has manufactured and have experience in magnetic separator manufacturing from last 35+ years. We have lots of experience to manufacture magnetic separator for recycling industries also. We manufactured highly advance and most efficient magnetic separator for recycling industries which can separate ferromagnetic parts such as iron, steel and other weak materials.

As well as our magnetic separator is very effective to separate non-ferromagnetic parts, such as aluminium, copper, zinc, gold, silver, and magnesium.

There are numerous applications which can use our magnetic separators. These include separation and recovery of metallic element and non-ferrous metals as well as the elimination of impurities from product flow.

Now,

Here we briefly discuss our magnetic separators:

Jaykrishna Magnetics Pvt. Ltd. has developed very efficient magnetic separator for recycling industries.

- Eddy Current Separator

- Suspension Magnet

- Overband Magnetic Separator

Above three magnetic separators are our most demanded product in recycling industries.

#1. Eddy Current Separator:

Eddy current separator is our most effective and innovative magnetic separator for recycling industries. Our eddy current separator is known as the fastest magnetic separator for recycling industries. In our eddy current separator, we used powerful magnets to separate non-ferrous metals from waste.

Our eddy current magnetic separator is a most advance magnetic separator in today’s market which is mostly used to separate non-ferrous metal form the waste. Our eddy current magnetic separator is highly efficient to separates aluminium, copper, brass and other non-ferrous metals from any product stream.

In eddy current separator there is a short belt of conveyors that has its drive located at the return end and a high-speed magnetic rotor system installed at the discharge end. A magnetic rotor, which is positioned within a separately rotating non-metallic drum, revolves high speed during operation whilst the outer drum cover rotates at the speed of the eddy currents belt conveyor.

While rotor spins at these high speeds at that time the electric current is induced into conducting metals. The induced electric current produces a magnetic field, which opposed the field created by the rotor, repelling the conducting metals over a pre-positioned splitter plate. The remaining materials such as plastics, glass, and other dry recyclables will simply free-fall over the rotor, separating them from the repelled metals. We have used 2 vibratory feeders in our machine for the effective separation process.

Salient Features:

- Solid structure with anti-vibration pads.

- No loss of valuable material.

- Low maintenance.

- Protected other recycling equipment.

- High yields of non-ferrous metals recovery.

#2. Suspension Magnet:

Jaykrishna Magnetics Pvt. Ltd. has manufactured a highly efficient suspension magnet for recycling industries. Our suspension magnets are very useful to remove non-ferrous metals from the waste. We use rare earth magnets in our suspension magnets so it can provide high efficiency in recycling industries.

The suspension magnet is installed at the discharge of the head pulley or above the conveyor belt. Whenever the waste material passes under the magnet, metal impurities are drawn out of the material. Material which is flowing freely can be thrown into the front side of the magnet which increases the separation result. Suspension magnet can be suspended from a traveling trolley so that it can be moved away from the conveyor to be cleaned manually.

Simply it attracts the iron particles and moved out of the magnetic area by pushers. Once they have left the magnetic field, the ferrous particles fall into a collecting device. Simply it attracts the iron particles and moved out of the magnetic area by pushers…

Salient Features:

- Heavy duty magnetic plates

- Robust construction

- No power supply required

- Low maintenance

- Self-cleaning

- Powerful Magnets

- No breakdown

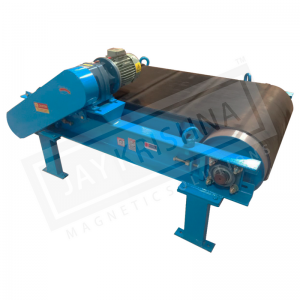

#3. Overband Magnetic Separator:

Overband magnetic separator is used to remove impurities like steel, metal, aluminium, brass, etc. from the waste in recycling industries. As we know the value of recycled material is very high in today’s market so the overband magnetic separator is useful in the process of recycling of waste materials. Our overband magnetic separator separate metal and other non-ferrous materials from the waste.

The overband magnetic separator is highly recommended for recycling industries. Overband magnetic separators are very efficient & effective separate ferrous metals from small to big sizes or recover ferrous metals from higher materials depth, or high speed.

Our overband magnetic separators made with ferrite magnets, neodymium magnets, electromagnets or by special combination are up to every task.

Salient Features:

- Most effective for removal of tramp iron from materials carried over conveyors

- High efficiency

- cost savings

- Maintenance free

- Guaranteed performance

- Dust and rain protection

- Easy to install

- Powerful to remove the big size of impurities

Jaykrishna Magnetics Pvt. Ltd. is manufacturing eddy current separators, overband magnetic separator, and suspension magnets with long lasting strength and high-power magnets. We used high-quality magnets which are used in the separation process of metals. We are providing the best quality separators that satisfy industrial needs. We have customers who appreciated our magnetic separator.

So, if you are looking for magnetic separator for metal recycling,

Jaykrishna Magnetics Pvt. Ltd. provides the best quality magnetic separators. For any requirement contact us at info@jkmagnetic.com