Top 5 Magnetic Separation Challenges in Waste & Recycling—and How to Overcome Them

Magnetic separation in waste and recycling operations faces serious challenges that can strongly impact recovery rates, operational efficiency, and bottom-line profitability. From pollution issues to equipment maintenance concerns, these obstacles require strategic solutions and the right industrial separation equipment to overcome.

Whether you’re managing a scrap recycling facility, municipal waste processing plant, or material recovery facility, understanding these challenges—and their proven solutions—can transform your operation’s performance. At Jaykrishna Magnetics, we’ve worked with hundreds of facilities to optimize their magnetic separation processes across different recycling applications.

What Are the Biggest Obstacles in Magnetic Separation for Recycling?

Today’s recycling facilities handle much more complicated waste than ever before. Old-style magnetic separators simply can’t keep up with the mix of materials coming through the doors.

Think about what gets recycled now: smartphones with multiple metals stuck together, car parts made from different materials bonded as one piece, and general waste mixed with all kinds of metal scraps. This messy combination creates serious problems that need better magnetic equipment and smarter setup strategies.

Challenge #1: Non-Ferrous Metal Discharge Reduces Recovery Efficiency

The Problem: Non-ferrous metals like aluminum, copper, and brass cannot be separated using traditional magnetic separators, leading to contaminated ferrous streams and lost revenue opportunities.

Why It Matters: Non-ferrous contamination can reduce the value of recovered ferrous materials by 15-30% and represents missed revenue from valuable metals like copper and aluminum.

The Solution: Implementing eddy current separators creates powerful electromagnetic fields that attract non-ferrous metals, enabling clean separation. These systems work best when positioned after initial magnetic separation stages.

Best Practices:

- Install eddy current separators across from drum magnetic separators

- Optimize belt speed and magnet strength for specific material types

- Regular monitoring ensures consistent separation performance

- Consider combination systems that integrate multiple separation technologies

Real-World Impact: A California recycling facility increased their non-ferrous recovery by 40% and improved ferrous purity to 98% after installing a properly configured eddy current separator system.

Challenge #2: Fine Particle Separation Creates Recovery Losses

The Problem: Traditional magnetic separators struggle with particles smaller than 2-3mm, leading to significant losses of valuable ferrous materials in fine fractions.

Why It Matters: Fine ferrous particles often represent 10-20% of total recoverable material but are frequently lost to waste streams due to improper separation technology.

The Solution: High-intensity rare earth magnetic equipment and specialized inline drum magnetic separators provide the powerful magnetic fields needed for fine particle recovery.

Equipment Recommendations:

- Rare earth magnetic pulleys for conveyor applications

- High-intensity drum separators with multiple magnetic zones

- Magnetic destoners for removing fine ferrous particles from aggregate materials

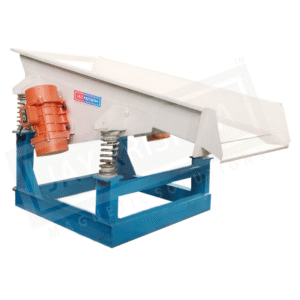

- Vibratory feeders to provide optimal material presentation

Implementation Strategy:

- Position high-intensity separators at material discharge points

- Use vibratory screening machines to pre-size materials for optimal separation

- Install drawer magnets in material flow paths for continuous fine particle capture

Challenge #3: Inconsistent Material Flow Impacts Separation Performance

The Problem: Irregular material flow, surging, and bridging create uneven magnetic field exposure, reducing separation efficiency and equipment performance.

Why It Matters: Inconsistent flow can reduce separation efficiency by 25-40% and cause premature equipment wear, increasing maintenance costs.

The Solution: Proper material handling with vibratory feeders and flow control systems ensures consistent, optimized material presentation to magnetic separators.

Flow Optimization Strategies:

- Electromagnetic vibratory feeders provide precise flow control

- Bin activators prevent material bridging and ensure consistent discharge

- Vibratory tables create perfect material distribution

- Spiral elevators manage vertical material transport without segregation

System Integration:

- Coordinate feed rates with separator capacity

- Install electromagnetic vibrators for consistent material conditioning

- Use impact vibrators to prevent material collection

- Position grill magnets at feed points for initial contamination removal

Challenge #4: Moisture and Debris Activity Affects Magnetic Performance

The Problem: Wet materials, organic debris, and sticky contaminants reduce magnetic field effectiveness and cause equipment fouling.

Why It Matters: Moisture and debris can reduce magnetic separation efficiency by 30-50% and require frequent equipment cleaning, increasing operational costs.

The Solution: Pre-processing with magnetic destoners and moisture management systems, combined with self-cleaning magnetic equipment.

Moisture Management Approach:

- De-oiling vibrating screens remove liquid contaminants

- Magnetic coolant separators handle wet ferrous materials

- Plate magnets and hump magnets provide self-cleaning operation

- Mining magnets capture ferrous materials at transfer points

Equipment Selection for Wet Applications:

- Electromagnetic overband separators with wash-down capabilities

- Suspension magnets for overhead installation above wet materials

- Magnetic lifting equipment designed for harsh environments

- Trap magnets with easy-clean designs for contaminated streams

Challenge #5: Equipment Maintenance and Downtime Impact Productivity

The Problem: Traditional magnetic separators require frequent cleaning, maintenance, and replacement, causing costly production interruptions.

Why It Matters: Unplanned downtime can cost recycling operations $5,000-$15,000 per hour, while inadequate maintenance reduces equipment lifespan and performance.

The Solution: Self-cleaning equipment designs, and predictive maintenance programs minimize downtime while maximizing equipment reliability.

Maintenance-Optimized Equipment:

- Electromagnetic ferro filters with automatic cleaning cycles

- Magnetic sweepers for continuous area cleaning

- Electromagnetic lifters with controlled release mechanisms

- Overband magnetic separators with belt cleaning systems

Maintenance Best Practices:

- Implement vibration monitoring on vibratory motors

- Schedule preventive maintenance during planned shutdowns

- Use magnetic sorting belts with quick-change capabilities

- Install vibrating screening machines with accessible cleaning points

Magnetic Separation Equipment Comparison for Recycling Applications

| Equipment Type | Best Application | Particle Size Range | Maintenance Level | Cost Effectiveness |

|---|---|---|---|---|

| Drum Magnetic Separator | General ferrous recovery | 3mm+ | Medium | High |

| Eddy Current Separator | Non-ferrous separation | 5mm+ | Medium | Very High |

| Rare Earth Magnets | Fine particle recovery | 0.5mm+ | Low | High |

| Electromagnetic Overband | Continuous operations | All sizes | High | Medium |

| Magnetic Destoner | Aggregate cleaning | 2–50mm | Low | High |

| Vibratory Feeders | Flow control | All sizes | Low | Very High |

How Do You Choose the Right Magnetic Separation Solution?

Selecting optimal magnetic separation equipment depends on several critical factors that determine both performance and return on investment.

Material Characteristics Assessment:

- Particle size distribution and ferrous content

- Contamination types and concentration levels

- Material flow rates and processing volumes

- Moisture content and physical properties

Operational Requirements:

- Available installation space and conveyor integration

- Power requirements and utility availability

- Maintenance capabilities and staffing levels

- Environmental conditions and safety requirements

Performance Expectations:

- Required recovery rates and purity levels

- Processing capacity and throughput demands

- Integration with existing equipment

- Future expansion and modification needs

What Maintenance Practices Maximize Magnetic Separator Performance?

Proper maintenance extends equipment life, maintains separation efficiency, and prevents costly unexpected failures.

Daily Maintenance Tasks:

- Visual inspection of magnetic fields and material flow

- Cleaning of grill magnets and plate magnets

- Monitoring vibratory feeder performance

- Checking drawer magnet collection levels

Weekly Maintenance Schedule:

- Deep cleaning of electromagnetic equipment

- Inspection of magnetic pulley surfaces

- Vibratory motor lubrication and alignment checks

- Performance testing of magnetic coolant separators

Monthly Preventive Maintenance:

- Magnetic field strength testing

- Electromagnetic separator coil inspection

- Vibrating screening machine component replacement

- Calibration of magnetic lifting equipment

Ready to Optimize Your Magnetic Separation Process?

Overcoming magnetic separation challenges requires the right combination of equipment, expertise, and strategic implementation. At Jaykrishna Magnetics, our complete range of magnetic separators, vibratory equipment, and electromagnetic systems provides proven solutions for every recycling application.

Take Action Today:

- Get a Free Consultation: Contact our separation experts to assess your specific challenges and requirements

- Explore Our Solutions: Visit jkmagnetic.com to view our complete range of magnetic separation equipment

- Request a Custom Quote: Let us design a specialized solution that maximizes your recovery rates and operational efficiency

Don’t let magnetic separation challenges limit your facility’s potential. Partner with Jaykrishna Magnetics to transform your recycling operation with proven, reliable magnetic separation technology.

Frequently Asked Questions About Magnetic Separation in Recycling

Q: What’s the difference between electromagnetic and permanent magnetic separators for recycling?

A: Electromagnetic separators offer adjustable magnetic field strength and can be turned off for maintenance, making them ideal for continuous operations. Permanent magnetic separators require no power but have fixed field strength, making them perfect for consistent applications with lower maintenance requirements.

Q: How do eddy current separators improve non-ferrous metal recovery?

A: Eddy current separators create powerful electromagnetic fields that repel non-ferrous metals like aluminum and copper, launching them away from other materials. This enables recovery of valuable non-ferrous metals that traditional magnets cannot capture, typically increasing recovery rates by 35-50%.

Q: What maintenance is required for vibratory magnetic separation equipment?

A: Vibratory equipment requires regular lubrication of motors, inspection of springs and mounts, and monitoring of vibration patterns. Most vibratory feeders and screens need weekly lubrication and monthly alignment checks, with bearing replacement typically required annually.

Q: Can magnetic separators handle wet or contaminated materials effectively?

A: Yes, specialized equipment like magnetic destoners and electromagnetic overband separators are designed for wet applications. However, pre-processing with de-oiling screens and proper drainage systems significantly improves performance and reduces maintenance requirements.

Q: How do you calculate ROI for magnetic separation equipment investments?

A: ROI calculation should include increased material recovery rates, improved product purity premiums, reduced contamination penalties, and decreased manual sorting costs. Most facilities see payback periods of 12-24 months when properly implemented magnetic separation systems increase recovery by 20-30%.